When 2021 hit, the world was ready for the New Year. Even if it brought with it a New Normal -- new way of doing business, a new way to shop for groceries and more -- the turning of the calendar meant putting a year of supply chain disruptions, restaurant closures and constant pivoting behind us.

But, then, on March 23, a stranded Evergreen container ship blocked navigation in Egypt’s Suez Canal, setting the stage for what would be a slew of supply chain disruptions after supply chain disruptions.

Suddenly, 2021 was quickly becoming a mirrored reflection of the year prior.

Then came the ransomware attacks, internet outages, container ships stuck at bay, bridge closures, driver shortages, ingredient shortages, natural disasters and more.

The hits just kept on hitting.

And, industry experts are already showing signs of struggle for 2022 into 2023, as routes to import/export remain clogged, ports continue to be backed up, cost of doing business increases and the labor shortage exists.

“Supply chain challenges will continue to be an issue throughout 2022, as the pipeline of imports received via ships and railways remains clogged, truck drivers are in short supply, home-bound consumers purchased more items for at-home use and production facilities remain labor challenged,” adds Brian Numainville, principal, The Feedback Group. “And, we are again seeing limits placed on products in retail stores as rolling shortages are expected to continue. It’s definitely going to continue to be bad before it gets better.” [CLICK HERE to read the full interview with Brian Numainville].

That’s because supply chains are messy. And, they’re only going to get worse before they get better.

McKinsey & Company’s recent research found that over a 10-year period, firms may lose 42% of their annual profits due to disruptions.

Companies are rushing to implement cloud-based solutions, supply chain visibility, digitalized planning and more. They’re relying on real-time data, emerging technologies and hyperconnected supply chains to keep disruptions at bay. They’re implementing programs that upskill and reskill employees, and preparing for what could become a very interesting peak season.

But, is it enough? Is it too late?

“Looking into 2022, I still see a lot of uncertainty and instability. There will continue to be supply chain challenges based on the volatility of the market, as well as labor shortages and continued increase in demand. This puts sustained pressure on labor, production and the entire end-to-end supply chain,” says Jaime Urquidi, regional VP and CPG lead at Parsable. “Depending on how we get out of that peak, demand will affect how long it takes the supply chain to stabilize next year.” [CLICK HERE to read the full interview with Jaime Urquidi].

Port congestion is also shooting up prices, according to Joe Shone, head of enterprise product sales at Uber Freight.

“Even though imports constitute a small portion of U.S. freight, congestion has left many imported goods stuck at ports and caused retailers to settle for high prices to get their goods out before the holidays,” Shone adds. “On the driver supply side, we are still in the midst of a massive driver shortage. The semiconductor shortage continues to constrain capital supply, and the driver market is still recovering from the pandemic. However, we have seen drivers slowly coming back into the market (especially in the long-haul sector) since some states ended their unemployment insurance programs. Spot rate growth has decelerated in those states.” [CLICK HERE to read the full interview with Joe Shone].

However, for many in the supply chain industry, there’s only one way to go, and that is up.

Here’s how technologies, visibility and the drive to overturn the labor shortage will help improve the current state of the supply chain.

Overcoming labor shortage

Anyone and everyone in the supply chain industry is hiring. And, while automation and robotics are key to filling some of these gaps, the supply chain still needs human beings to move product through the cold food chain.

“Recruiting and retaining talent in warehouses and transportation companies is one of the biggest challenges the industry is facing. One way that companies are adapting to the future is looking to automation, but they are also looking to being creative when it comes to finding and keeping talent. The increased recognition of the importance of the food supply chain will hopefully attract new talent, especially since these are essential businesses that are critical and will continue operation no matter the circumstance,” says Matthew Ott, president and CEO of the Global Cold Chain Alliance (GCCA).

Aside from flexible hours, improved work/home balance, sign-on bonuses and more, companies are also implementing technologies to help employees do their job in a safer, more efficient manner.

“The pandemic has had a clear and unmistakable impact on the labor force, with many opting to change careers or retire if they are able,” says Numainville. “Workplace safety, increased wages and flexibility are now table stakes for workers as they look at their options. There are several things companies should be doing in the hiring process – online interviewing and recruiting is a must, for example, with quick turnaround from interview to hire. There are so many companies looking for workers that if you aren’t easy to navigate in the hiring process, the candidate will go elsewhere quickly. Same applies for the onboarding process – it needs to be efficient, easy to navigate and integrate. As far as retention, flexibility and clear communication of what you are doing to ensure safety are key. Overall, companies need to tell a clear and compelling story about why they are the place to work.”

Companies are also encouraged to re-create the role and think more outside of the box when looking for new talent.

“The industry has traditionally hired from very specific segments of the population, but those segments are no longer sufficient in filling the need for new entrants. The industry as a whole needs to embrace diversity and inclusivity efforts in order to start attracting greater numbers of workers from non-traditional sources,” says Mark Murrell, president and co-founder of CarriersEdge in Food Logistics’ September 2021 issue.

However, one of the best thing companies can do to manage the labor shortage is retain the employees they currently have, says Alex Wakefield, CEO, Longbow Advantage.

“One of the ways we’re seeing companies do that is by implementing pay-for-performance programs in the warehouse. In distribution centers where we’ve seen them implemented, employees are often seeking out management to better understand their performance and learn how that can maximize their impact, creating a feedback loop that can be used to increase performance, engagement and satisfaction,” Wakefield says. [CLICK HERE to read the full interview with Alex Wakefield.]

In the material handling space specifically, where forklift operators sometimes work in sub-zero temperatures, the hiring and onboarding process is crucial. That’s why companies are encouraged to streamline onboarding and encourage the retention of forklift operators by enhancing the operator experience and helping newly trained operators gain confidence and increase productivity while maintaining a strong safety culture, says Andrew Smith, director, marketing product management, Crown Equipment Corporation.

In response, Crown Equipment developed the InfoLink forklift fleet management system, which gathers data to help enhance operator engagement and safety.

“Customers can use the system to limit access to the equipment to only those with the proper training. Companies can also customize electronic inspection checklists with unique questions to ensure operators have appropriately inspected the equipment. The data gathered through the system can also be used to identify operators exhibiting correct and incorrect behaviors and opportunities for supervision and reinforcement of training,” says Smith. Crown’s InfoLink system, and the data it gathers, can help enhance operator engagement and safety.Crown Equipment Corporation

Crown’s InfoLink system, and the data it gathers, can help enhance operator engagement and safety.Crown Equipment Corporation

Understanding the important nuances within a specific market, such as shift start times and traffic patterns, can also make a difference in attracting and retaining employees, says Darin Cooprider, SVP, consumer packaged goods, Ryder.

“The ability for employees to select different shifts and coverage from week to week, depending on their preference and at-home responsibilities, can be a large area of differentiation,” he adds. “Rapid escalation in wage rates for frontline workers in particular are making it increasingly more challenging to attract and retain workers. Younger workers are also looking for a company where they feel appreciated, valued and have growth opportunities, requiring companies to rethink how they engage with employees to differentiate themselves. With this rapid escalation of wages, the increased demand for automation continues to accelerate the technology and expand the ROI analysis to include worker availability (at any cost).”

What’s more is, the conversation around the gig economy is far from over.

“Independent contractor rights, security and 1099 worker benefits are all pieces of the labor puzzle where we anticipate a lot of change,” says Aaron Hageman, CEO, Delivery Drivers, Inc. “Additionally, the tides of our customers’ delivery demands will continue to rise next year and there will be more growth. With more demand than ever, we are starting to see the next round of technology solutions that allow our retail partners to leverage many different omnichannel fulfillment solutions. One size rarely fits all these days for retailers, particularly in cold chain fulfillment where we cannot stack orders on top of each other.” [CLICK HERE to read the full interview with Aaron Hageman].

Click here to hear more about the driver shortage:

Technology takes supply chains to next level

From truck and rail to ship and air, the transportation sector has undergone a series of re-developments since the onset of the Coronavirus disease (COVID-19).

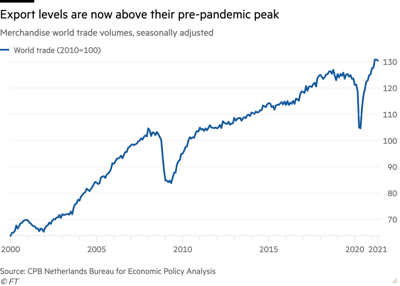

The World Trade Organization (WTO) says volume of world merchandise trade is expected to increase by 8% in 2021 after falling 5.3% in 2020. However, trade growth is then projected to slow to 4% in 2022, as detailed in Food Logistics’ May 2021 issue.

Rising import prices and the need to nearshore continue to compound an already complex shipping supply chain. As of October, some 77 cargo ships were at a standstill outside of California ports, forcing the Port of Los Angeles and Port of Long Beach to move to 24 hours/7 days a week operations. International trade recovered at the end of 2020 to pre-Coronavirus levels, and trade levels were 0.6% higher, mainly helped by exports from advanced economies and by imports from emerging economies, according to CPB.CPB Netherlands Bureau for Economic Policy Analysis

International trade recovered at the end of 2020 to pre-Coronavirus levels, and trade levels were 0.6% higher, mainly helped by exports from advanced economies and by imports from emerging economies, according to CPB.CPB Netherlands Bureau for Economic Policy Analysis

Supply chain industry experts predict such shipping problems to linger into 2022; in fact, shipping a container through major U.S. ports now takes triple the time it did pre-pandemic.

Likewise, third-party logistics (3PL) providers are adapting to the influx of automation by embracing online tools for communication, education and streamlining workflow. They’ve had to re-think old processes, more specifically with regards to pricing, forecasting, route planning and more. And, to overcome supply chain disruptions, data, flexibility and visibility will be key in navigating the business landscape.

“Visibility with collaboration are significant challenges – and also opportunities – for the food and beverage industry with its strict time and temperature controls. The pandemic has only exacerbated the issue, as consumer buying trends increasingly favor e-commerce with more first-time adopters of CPG products,” says Cooprider.

In response, Ryder introduced RyderShare, a collaborative logistics platform designed to eliminate industry silos and enable everyone involved in moving goods through supply chains, including shippers, receivers, carriers and service providers, to work together in real time.

“Visibility technology will continue to play a vital role in the cold chain. Real-time cargo temperature tracking and visibility is becoming more prevalent. Trailers configured with the means for tracking and reporting will increasingly become table stakes. And, real-time temperature, humidity and environmental monitoring within segments of facilities can enhance and assure product quality while providing communication to producers,” he adds.

That's why it should be noted that many raw materials still originate from areas with little to no access to internet, says Waylon Sharp, VP and COO of food and agriculture at Bureau Veritas North America.

"Such investments extend how that information is then aggregated and customized to become actionable by customers to the betterment of food safety," Sharps adds. [CLICK HERE to read the full interview with Waylon Sharp].

In response, Bureau Veritas launched Supply-R in July 2020 to address visibility challenges. Supply-R is a digital solution designed to meet companies’ new challenges relating to supplier network reliability and ensuring business continuity in all circumstances.

"Digital supply chain management solutions can help minimize shocks to demand, pricing and logistics, and drive supply chain value through a focus on risk management and process control," Sharp says.

For some companies, there may not be one type of technology that makes the difference.

“I believe it’s a matter of bringing everything together in a connected platform to create a more connected supply chain. I’m a firm believer that blockchain and IoT will continue to grow in popularity and give us much better visibility and understanding of the real-time movement of goods,” says Dan Clark, VP of product innovation and strategy, Trimble Transportation. “The good news is that it is no longer necessary to build solutions separately – you can connect to existing tools and partner with organizations that can bring all data to a central repository for easier integrations between technology. We’re continuing to move toward more platform-agnostic solutions that can connect to so many different providers and all types of solutions securely.

“Carriers, shippers and brokers all need to share the same information in order to be effective, so for technology providers, the challenge has long been finding a way to integrate effectively between partners. But, if you’re all operating on the same platform, there’s no need to integrate because the data is already there and shared by all parties. This is the vision that Trimble has, for a truly connected supply chain where all stakeholders can collaborate more effectively in a single platform,” Clark says. [CLICK HERE to read the full interview with Dan Clark].

Full supply chain visibility can only be achieved once silos are eliminated, according to Patty McDonald, head of solution marketing, Symphony RetailAI. “Currently, many retailers face challenges to see where their inventory is at every step of the supply chain. What’s more, omnichannel has only added to this complexity – activity in one channel has a direct impact on other channels and retailers must be able to understand these dynamics,” she adds. “Our AI-based technology and master data management enables retailers to access inventory availability across the supply chain. In turn, this allows them to confidently predict changes in demand and respond rapidly, no matter how seemingly unexpected the change is. What’s more, our technology enables retailers to support complex logistics networks by sourcing and pulling product from multiple locations and/or vendors during a period of disruption.” [CLICK HERE to read the full interview with Patty McDonald].

Plus, right now, there is an emphasis on software that brings together a myriad of data from track-and-trace devices, apps, EDI-generated signals, APIs and more.

"Such software helps piece together a better picture of where shipments and the products in them are or were last seen to then provide users with not only better visibility, but [also] better anticipation and better adaptation so that logistics and supply chains can plan and execute better," says Michael Zimmerman, partner, Kearney. [CLICK HERE to read the full interview with Michael Zimmerman].

In order to restore a healthier balance in the food supply chain in 2022, companies should look to invest in freight automation platforms to achieve greater connectivity between all parties involved, according to Doug Schrier, SVP of strategy at Transflo.

“A lingering source of inefficiency in the supply chain is the lack of the ability for shippers and receivers to communicate with the drivers coming into their facilities to pick up or drop off a load. Shippers have invested heavily in tools like yard management systems and other management software, but those often don't connect with the tools the drivers are using. So, the goal is to partner with those shippers who've made these investments and to bring drivers into the fold. This maximizes the opportunities of the software investments by both sides. The way to do this is to connect shippers with the motor carriers and the drivers who are executing their freight, which enables them to move that freight in a much more efficient way,” he adds.

As a result, Transflo introduced Transflo Intelligent Automation, a suite of document automation services that provide tools to carriers, freight brokers, providers, shippers and freight auditors to manage and process load documents and paperwork.

Transflo Intelligent Automation (TIA) automatically processes and delivers data to pre-selected fleet personnel and integrates into accounting, invoicing, maintenance reporting, and transportation management system platforms.Transflo

Transflo Intelligent Automation (TIA) automatically processes and delivers data to pre-selected fleet personnel and integrates into accounting, invoicing, maintenance reporting, and transportation management system platforms.Transflo

“When parties use digital paperwork, it acts as a bridge between the various management platforms, allowing shippers' yard management systems to effectively talk with carriers' fleet management tools. This opens up functions like allowing drivers to pre-register their load for pickup or drop-off and to automate check-in with shipper and receiver facilities,” adds Schrier. “In turn, this means drivers can receive a dock to load and unload more quickly, reducing the wasteful time that drivers and carriers spend in detention at these facilities and in effect, adding trucking capacity into the system. Detention costs everybody — freight shippers, carriers and drivers, receivers and the supply chain as a whole. So, finding ways to eliminate that waste can make a real difference. These are the types of systems we see playing a role in alleviating the stress on the system we've seen this year.”

Implementing autonomous technology within the yard will also provide accurate updates of the status of equipment at every stage, “resulting in 100% ‘clean data’ and much better visibility,” says Kyle Bertin, head of customer strategy and planning, Outrider. “However, visibility on its own isn’t simply enough. It’s also important to ensure that visibility isn’t siloed. It’s not very good, for instance, if you have great visibility to the state of your yard and your warehouse, but not enable that data to be exchanged easily. Clean data integrated within the supply chain is essential to achieve maximum efficiency and visibility, ultimately getting equipment, drivers and products on the road faster.”

Digital transformation is also deemed as one of the most significant disruptions to company siloes, fusing together all parties of an operation, end-to-end.

“Through digital transformation, organizations are harnessing both historical and real-time (or near real-time) data to proactively anticipate changes in demand and using automation to respond,” says Markus Schmidt, president of Swisslog Logistics Automation, Americas. “The key to harnessing the power of warehouse data lies in warehouse management and execution software. As warehouse software has evolved, siloes have been created with warehouse management, warehouse execution and automation control systems all operating in a way that leaves data isolated, limiting its potential to improve operations. Not only is data siloed between production and the supply chain that supports it, but within the supply chain itself. The new generation of warehouse management software integrates these various data streams into a single platform to unleash the power of the data. Moving storage and fulfillment closer to consumers, while maintaining the agility to quickly adopt to future volume changes as market demand shifts, will be an essential characteristic of the supply chain of the future.Swisslog Logistics Automation, Americas

Moving storage and fulfillment closer to consumers, while maintaining the agility to quickly adopt to future volume changes as market demand shifts, will be an essential characteristic of the supply chain of the future.Swisslog Logistics Automation, Americas

“This data is fuel for the artificial intelligence systems that will enable logistics systems to learn and evolve on their own. Through the power of data and artificial intelligence, supply chain systems will learn to recognize patterns, regularities and interdependencies from structured and unstructured data to anticipate demand and adapt, dynamically and independently, to new situations. Working with similarly intelligent productions systems, these self-learning supply chain systems will enable organizations to meet global customer requirements with greater speed, customization and efficiency,” he adds. [CLICK HERE to read the full interview with Markus Schmidt].

The cloud is another technology capable of ensuring visibility at every stage of the supply chain.

“With a cloud-based, all-in-one, comprehensive ERP system, enterprises can gain the foresight they need to improve their supply chain,” says Scott Deakins, Deacom business unit leader, ECI Software Solutions. “The perfect storm of 2021 exposed how fragile our advanced, global supply chain can be. Some company leaders didn’t even know their product went to the Suez until it was delayed. In the year ahead, we can expect to see more and more companies working with redundant partners in critical areas like raw materials or distribution solutions in several overlapping territories.” [CLICK HERE to read the full interview with Scott Deakins].

However, while some solutions provide the means for digitalization, they often do not resolve all of transportation challenges, adds Greg Foreman, VP operations, retail, DHL Supply Chain.

“Complementary software packages and deep transportation expertise are required to achieve true real-time visibility and optimize capacity utilization. Supply chain analytics and decision support tools have proven valuable in enabling site location decisions. While well established, these tools are continuing to advance in performance, primarily through the application of machine learning. They are also being augmented by new tools that enable use of much larger data sets to achieve levels of optimization not previously possible,” he says. [CLICK HERE to read the full interview with Greg Foreman].

What’s more is, the influx of 5G in the cold food chain continues to make solutions and technologies run smoother and more efficiently.

“Blockchain shows promise for compliance and tracking as an emerging technology. Cloud data storage and machine learning allows for the ability to harvest vast amounts of data from these devices and play into the efficiency cold food chain technology. From a sustainability standpoint, we are better able to manage a customer’s carbon footprint more effectively,” says Andy Moses, SVP sales and solutions, Penske Logistics.

Through the emergence of control tower technology, Penske’s ClearChain technology suite helps customers unify supply chain decision making across their various management structures.

Supply chain innovations have led to improved efficiency, reliability and profitability, but have also created new risks for supply chain companies. [DOWNLOAD this white paper to learn more].

But, thanks to ongoing supply chain disruptions, an upside-down supply and demand model and the challenge to recruit and retain quality works, companies should prepare for sustained periods of supply chain disruption, says Elizaveta Krieg, head of CUO property, Allianz Global Corporate & Specialty.

“The range and diversity of risks to supply chain is constantly growing and recent experience shows how far-reaching events like a pandemic, climate change, financial crises, trade tensions and political instability could be,” Krieg says. “The 2020 McKinsey analysis shows that averaging across industries, every company could expect a disruption lasting 1 month and longer, every 3.7 years, and this is the new reality for which insureds and carriers need to prepare for.”

Companies should also focus on utilizing real-time visibility solutions to create visuals, track shipments, test different scenarios and more.

“All the information from real-time visibility solutions needs to be integrated into specific business activities, such as labor planning and customer service. This information needs to be automatically shared with the appropriate parties and combined with other data, so operators and planners can make informed decisions. For example, production planners should automatically have information about the arrival time of key raw material deliveries as they set production schedules for the following week,” says Dustin Burke, managing director and partner, global co-leader of manufacturing and supply chain, Boston Consulting Group. “It’s important to note that the supply chain is about more than just logistics. The supply chain starts with the availability of raw materials and ends with the availability of workers to stock store shelves, consisting of everything else in between. The greatest challenges in the food supply chain result from food being disproportionately dependent on transportation and labor.” [CLICK HERE to read the full interview with Dustin Burke].

Plus, dependence on robust supply chain control towers will be essential to the future success of supply chains.

“The inability to manage supply and demand on a global basis is clearly becoming more acute. Considering the confluence and complexity of factors that are responsible for the unprecedented shortage of needed goods, current conditions are likely to intensify and become more challenging throughout 2022,” says C. John Langley Jr., clinical professor of supply chain management and director of development for Center for Supply Chain Research, Penn State University. “Unfortunately, the risk outlook for cold food chains will be impacted by the global volatility of markets, sources and prices of energy resources needed to maintain desired levels of temperature. While significant benefits may be related to the pursuit of environmental sustainability, the net results are likely to include adverse impacts on the availability and cost of energy resources for businesses and consumers.”

For its part, telematics delivers ways to monitor and control fleets, remotely.

“For example, [telematics is] reducing food loss by applying insights from refrigeration data streaming to the cloud from their vehicles through the Internet of Things. [It is] reducing downtime by closely monitoring operating performance to watch for signs of trouble. And, [companies are] using automation to perform tasks like pre-trip readiness checks to more quickly turn around loads. The massive volumes of data that are now available for fleets can be overwhelming, so fleets are looking for analytics to quickly understand what they are seeing and what actions to take next,” says Dominic Hand, VP IT and connected products, Thermo King. “Some fleets are using remote monitoring services with expertise in specific technologies like transport refrigeration to interpret the data and tell them when they need to take action to avoid downtime.”

Looking ahead to a brighter 2022

Despite the disruptions, attacks and other challenges plaguing the supply chain industry, the future remains bright for companies invested in deploying the right technologies, taking care of their people, instilling risk mitigation measures and enforcing food safety.

For instance, there will continue to be a strong emphasis on traceability.

“In fact, the FDA announced its plans to leverage technology to create a safer and more digital, traceable food system with the goal of reducing foodborne illness,” says McDonald. “Another continued focus as we head into 2022 will be proper operations around handling food items, such as the transportation and cutting of meat items. One problem in the supply chain can cause a ripple effect. Therefore, it’s critical to have inventory visibility with real-time updates, along with the agility to respond to and bounce back from challenges.”

What’s more is, monitoring products throughout their journey--from manufacturers/farms to stores and restaurants--will be instrumental in preventing contaminated or compromised products from reaching consumers, says Liz Sertl, senior director, community engagement, GS1 US.

“When a recall does become necessary, faster access to product and location data makes it possible to gain provenance and ascertain where a product has been without delay – speeding up the successful removal of suspect products and helping pinpoint the source of contamination. Scanning barcodes that are encoded with standardized product ID and attributes, including batch/lot numbers, improves the food system in several ways. It provides product traceability across the entire supply chain. More automation instead of manual data entry reduces human errors that cause failures throughout the cold chain (minimizing delays, erroneous product counts, etc.). The use of standardized product and location identifiers improves accuracy and quality of data exchanged between parties throughout the supply chain, which leads to more expeditious shipments, optimized space in trucks and better inventory management to improve freshness,” she adds. “Establishing consumer trust in this new environment will be a challenge for food suppliers, who will need to innovate and demonstrate collaborative efforts to help stabilize the system or offset new, volatile supply chain limitations.” [CLICK HERE to read the full interview with Liz Sertl].

And, the rapid continuous growth in the frozen foods sector presents different kinds of growth drivers where opportunities abound.

“The frozen food aisle has been a growth driver for retailers since 2016 with acceleration ahead of most other departments. In 2020, frozen foods proved to be a pandemic powerhouse ringing in $65.1 billion in retail sales. One of the biggest questions coming out of 2020 was, could frozen sustain these gains? All signs point to yes,” says Alison Bodor, president and CEO, American Frozen Food Institute (AFFI). “Looking at sales patterns of the past few years, it isn’t just one or two areas in the frozen food aisle that are driving growth; it’s quite literally all categories. Many categories play in breakfast vs. dinner, or indulgence vs. health. But, frozen foods cover it all -- functional and indulgence plus all meal occasions from breakfast, lunch and dinner to beverages, snacks and desserts. Lunch became a huge growth opportunity during the pandemic as consumers emphasize time and convenience. With many more consumers continuing to work from home part or all of the time, frozen foods will continue to make inroads across meal occasions. Online now represents about 10% of all food sold in the U.S. And, online growth has not yet plateaued with expected market penetration of about 12% by the end of 2021. Here too, frozen food rides a growth trend, with very high online conversion and penetration.” [CLICK HERE to read the full interview with Alison Bodor].

It's also best to prepare, plan and execute as far ahead as possible.

"In the cold food chain, timing is crucial. Prepare your order forecasts and pre-book your freight as far in advance as possible," says Lynn Stacy, managing director of OEC Group Liquid Logistic Solutions. "When it comes to the cold food chain, proper pre-planning is extremely helpful in a tight market. It’s also extremely important to familiarize yourself with every different cold storage warehouse, reefer container, ISO tank and Flexitank option. To pinpoint one product, the quality of orange juice varies greatly based on shipping method. In our highly congested market, insulated ISO tanks are not longer viable. Average dwell times and processing times have expanded, and insulation can no longer control the temperature long enough. Alternatively, a 40-inch HQ reefer holding a Flexitank can keep orange juice cold for a much longer period of time."

That’s not to say that employee retention won’t also be a main focus heading into 2022.

“Next to earnings opportunities and business-related costs like the cost of fuel, safety is a regular topic amongst frontline gig economy workers,” Hageman says. “The thing is, ‘driver safety’ is not a simple topic. There are many things that drive this conversation, including the need to carry cash (i.e. does your operating platform allow for or even promote cashless transactions). What options and choices do drivers have around cameras in the vehicles? Many drivers in our network have a desire to not use car signs or clothing that may identify them as a target. And, of course, no conversation about driver safety is complete without a comprehensive roundtable around COVID. If you haven’t already, start the conversation with your crews and find out how it manifests itself on the front lines day-to-day.”

Other conversations revolve around how to better promote the supply chain industry to those entering the field.

“The manufacturing industry needs to work to become more attractive to current and future employees. We need to make manufacturing more appealing and focus on the modern, digital aspects of the industry so that companies can attract top talent,” says Urquidi.

For transportation specifically, the dramatic rise in e-commerce, as well as click-and-collect services, continues to push last-mile delivery to the front, according to McDonald.

“The ability to manage timely delivery hinges on highly optimized logistics and accurate data. With fresh items, temperature and timing are critical surrounding delivery. As a result, access to data in real-time can help retailers effectively manage the movement of inventory through the supply chain and to the consumer,” says McDonald.

And, of course, data – how to collect it, what to do with it and who to share it with.

“As the supply chain continues to become more sophisticated and digitalized, data analytics is evolving into a powerful tool helping companies achieve greater supply chain visibility, flexibility and resiliency,” Foreman says. “The challenge many companies have is adequately identifying, prioritizing and acting on the data to deliver measurable, obtainable business goals and value, and ultimately, predictive insight. Most are barely scratching the surface when it comes to the business value that can be achieved through establishing data analytics processes. Whether they are tracking the wrong data or they do not have enough data or the right expertise to effectively analyze the data, many companies are missing vital opportunities to harness the power of data to solve their complex supply chain challenges.”

It's hard to say what this upcoming New Year will bring in terms of challenges and opportunities. Reverting back to how things were pre-pandemic would do a disservice to the technologies and innovations deployed and implemented to make the supply chain a safer, more efficient environment to move product.

For some industry experts, the future of supply chains present a more glim outlook.

"The current disruptions in supply chains will be resolved, but it may take the next 1-2 years, not months, to fully recover from the pandemic impacts," says John Paxton, CEO, MHI. "I believe disruption will be a normal condition moving forward, and companies will need to be able to adapt. Though no one wants disruptions in the supply chain, one outcome is that these disruptions have accelerated innovation as companies look for ways to adapt."

"I think the grocery and food trends that accelerated during the pandemic, such as e-commerce, home delivery and curbside pickup are here to stay," he adds. "However, as the pandemic wanes, consumers will return to some in-store shopping and to in-restaurant dining. The strategy for the future will be to offer all-of-the-above options, which means new strategies to deliver on this, including digital, automated supply chains and automated micro-fulfilment centers in the back of the stores." [CLICK HERE to read the full interview with John Paxton].

However, supply chain disruptions will continue to plague the industry, ransomware attacks and internet outages will continue to occur, container ships will still be stuck at bay, natural disasters will still strike and the driver shortage will still loom. But, the technology, visibility and drive to overturn the labor shortage will help improve the current state of the supply chain and present a brighter future.