To accelerate breakthrough innovation in supply chain management, leaders are increasingly employing the tools of benchmarking to identify opportunities and develop novel solutions.

Benchmarking empowers organizations to take actions that improve performance. Supply chain benchmarking can be aimed at supply chain planning, sourcing and procurement, logistics or manufacturing. Internal benchmarking makes comparisons against other parts of one’s own business (e.g., functions, product lines or geographies). External benchmarking makes comparisons against other organizations. Importantly, while external benchmarking can involve comparisons with companies in an organization’s own industry, often the most profound results are realized through benchmarking against organizations in seemingly disparate industries whose products or processes share ancillary characteristics.

A systematic approach to identifying new opportunities through benchmarking helps build a solid business case for new initiatives. Benchmarking results can also be used to set baselines for process improvement projects, to prioritize high-impact opportunities, and even to validate success or return on investment.

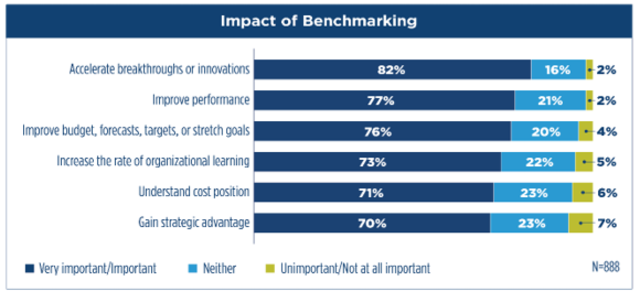

Recently, APQC surveyed 888 supply chain professionals who regularly practice benchmarking – the process of measuring and comparing a chosen set of variables (e.g., fuel usage, employee retention) internally or externally against others – to better understand how and why this practice is useful in managing supply chains. Asked what they view as important impacts of benchmarking, a whopping 82% of respondents, representing a variety of industries, agreed that the potential to “accelerate breakthroughs or innovations” was “very important” or “important” (See Figure 1).

APQC Fig. 1

APQC Fig. 1

Change your Improvement Trajectory

Finding jackpot comparisons outside your industry can lead to exponential – rather than incremental – improvements. For example, an airline once famously looked to NASCAR pit crews to improve turnaround times at the gate. A hospital made admission procedures vastly more efficient by studying hotel check-in practices.

Similarly, supply chains leaders can unlock innovation by finding organizations that use the same processes or concepts in very different contexts. A helpful framework for thinking through potential comparisons is the Theory of Inventive Problem-Solving, or TRIZ (“trees”). TRIZ involves framing problems as contradictions and using a set of 40 research-based principles to guide the problem-solver in developing solutions. The TRIZ methodology was originally developed by Genrich Altshuller, who analyzed more than 200,000 patent files to identify patterns of innovation. TRIZ has since evolved into a range of techniques and resources, many of which are available through open-source and educational outlets.

Get the Most Out of Benchmarking

Supply chain leaders recognize the immense value of benchmarking. Through the Evolution of Benchmarking research, APQC found that leading supply chain functions tend to make benchmarking an integral part of their culture rather than an ad hoc effort. Among the 2,024 participants who took the global survey, more than 44% currently use benchmarking as a strategic management tool in supply chain management. Between 2018 and 2021, the use of benchmarking in supply chain increased by nearly 50%. We expect to see further adoption growth by 2024.

APQC also found that the most common uses of benchmarking in supply chain are determining the potential size of the benefits from tackling an opportunity and establishing and measuring against performance targets.

Although benchmarking presents the opportunity to obtain rich and beneficial information, organizations may not be making full use of this tool. For example, nearly half of organizations (48%) that benchmark supply chain identified a lack of common definitions and process frameworks as an obstacle to benchmarking. Effective benchmarking requires shared language among all participants to ensure valid comparisons. Process frameworks like APQC’s Process Classification Framework® (PCF) provide a common language and definitions for processes to help organizations get the most out of their benchmarking efforts.

Supercharge Strategy

Benchmarking can be a catalyst for change. It is the systematic process of searching for best practices, innovative ideas, and more productive operating methods. Comparative information that shows key performance gaps can spark improvements and focus limited resources.

But benchmarking is only useful if it prompts change within the organization. For this reason, it should be used at the highest levels to help drive strategic decisions. Supply chain professionals understand this. Because supply chains are data-intensive, managers often seek evidence of performance gaps and ways to improve processes. Nearly two-thirds (65%) of supply chain respondents consider benchmarking to be “very important” for organizational strategic management.

Supply chain leaders should therefore take steps to ensure that benchmarking becomes an integral part of organizational decision making. Leading the charge to quantify the impacts of benchmarking to the organization and exposing a variety of employees to benchmarking practices can help increase buy-in and ensure continuity for these efforts.

Without a rigorous approach to external benchmarking, organizations risk succumbing to market forces as environments shift and new problems arise. Today’s competitive landscape demands that organizations carefully track and examine their performance and processes as a way to surface opportunities for innovation and reinvention.