Ensuring food safety along the cold food chain is a continuous ordeal, one that requires all parties, farm to fork, to participate in. And because rules and regulations continuously change, so too will the processes of growing, manufacturing, packaging and shipping be required to pivot accordingly.

In Food Logistics’ Sept/Oct 2022 issue, editor-in-chief Marina Mayer talks with several industry experts about food safety management, food safety culture, fact vs. fiction and more.

Here’s an interview with Shaun Trejo, chief revenue officer, CMX, who details why having a robust product lifecycle management strategy is a key method of improving food safety, with excerpts publishing in Food Logistics’ Sept/Oct 2022 issue. [CLICK HERE to read the article in full].

Food Logistics: When it comes to ensuring food safety in the cold chain, what are some of the major challenges companies face and why?

Shaun Trejo: Probably one of the biggest challenges is getting, and keeping, all the employees and partners on the same page regarding food safety. Fortunately, modern-day digital risk management platforms help tremendously in managing the cold chain and keeping food safe and of high quality until it arrives at the local grocer, restaurant or fast food outlet. However, it’s very important to view the entire cold chain as consisting of multiple links. It consists of many different employees and participants—from farm, to warehouse, to store. All these supply chain partners must each do their part. The cold chain can fail even if there is only one weak link.

For example, if a delivery truck’s doors are damaged, then it leads to improper temperatures, which affects its refrigeration capabilities. Also, if quality control (QC) employees do not accurately record temperatures, then they might miss a compromised temperature, which can lead to spoiled or unsafe food.

Profits can only be maximized when as much as possible of all produce is safe and usable—that is, by maintaining the integrity of the entire cold chain, which can only really happen if a company uses a dedicated, digital risk management platform.

At the end of the day, it’s crucial that everyone understands the importance of maintaining the cold chain—especially regarding what can happen when it’s not maintained—and that no one develops a careless attitude towards food safety.

Food Logistics: President Biden signed an Executive Order that will promote fair and competitive agricultural markets, prevent abuse of farmers by poultry processors and make prices fairer for farmers and American consumers. What does this mean for the future of food safety?

Trejo: Generally speaking, prices increase when there is little to no competition between producers. That’s because monopoly owners have much more control over the markets, and can therefore ask high prices for goods, even if the goods aren’t up to standard. Consumers don’t have much of a choice by way of getting guaranteed quality products for their dollars. Plus, primary producers—farmers in terms of the food industry—are underpaid for their produce since they have only a few options in terms of where they sell their goods. This principle goes for all sectors, including the food industry.

One big problem is that corporations often import meat from overseas instead of sourcing locally, and before the executive order, such meat could be labeled as “Product of USA” even if it was only processed in the U.S. That meant consumers really had no idea where their meat came from and whether it was safe and up to standard. Now, consumers will be able to know exactly where their meat comes from and can make better informed choices about what they buy, and whether to support local farmers and ranchers.

This will hopefully force bigger corporations to source produce, such as meat, more responsibly—for example, from local farmers and ranchers, instead of importing from overseas—and to ensure that such products are safe and up to standard.

Another thing is that farmers are often exploited in the sense that they don't have much choice in where they buy farming inputs, such as seeds and fertilizer, due to large corporations having monopoly shares. As such, farmers often don’t know exactly what the origins are for many of their farming inputs. Fairer markets should reduce the exploitation and underpayment of farmers, which will hopefully enable them to acquire higher quality inputs, which will result in the production of higher quality food. Also, farmers that speak up against abuse often face retaliation from big corporations, which make them hesitant to expose unsafe food practices. The executive order aims to address this, and the hope is that there will ultimately be more transparency and accountability regarding food production overall.

All these measures aim to incentivize the production of high-quality food, thereby improving food safety as a whole.

Food Logistics: A recent study reveals the food and beverage sector has experienced the most cargo theft. What solutions or technologies are in place to better secure loads of perishable goods?

Trejo: The problem of increased cargo theft is largely a result of the COVID-19 pandemic. A reduced workforce and growing consumer demands triggered a large disruption in supply chains, which caused large backlogs and delays at ports around the world. So cargo that used to be unloaded and distributed relatively quickly has now remained stationary for much longer. This has created more opportunities for thieves to target these stationary containers. Therefore, a major part of the problem lies at the storage facilities.

Apart from standard things such as CCTV monitoring and alarms, measures can be incorporated into cargo to track products and make them tamper proof, such as smart labels (e.g., radio-frequency identification tags) and tamper-evident seals. Since food and beverage items are a big target, using discreet packaging could also help mislead thieves.

In terms of technology, companies can first of all make sure they charter reputable distributors with high-tech security measures already in place. Then, having a digital platform in place to conduct regular self-assessments using automated checklists will ensure higher security. Training is also crucial; employees should ideally be trained in cargo theft prevention, for example, how to spot fake credentials if a driver and truck is arriving for a pickup. Warehouse management is also crucial; inventory should accurately be tracked at all times—this is yet another place where a digital risk management platform is key, for example in creating automated daily checklists.

Finally, increased supply chain digitization also creates more opportunities for cybercriminals to hack these systems and processes (as with most other technologies). To combat this, companies should invest in a digital platform that already accommodates appropriate cyber protection against such attacks.

Food Logistics: Food safety vs. food insecurity. How do the two relate and differ?

Trejo: Food safety is the need for food that is free from chemical, microbiological, or physical contamination. Food insecurity occurs where there is simply no access to food, where there is not enough food, or where the available food lacks the proper amount of nutrition, whether safe or unsafe.

It’s easy to think of it this way, there can be enough food and it can be highly nutritious and easily accessible, but if it’s contaminated, there’s a lack of food safety which could lead to food poisoning. On the flip side, food can be completely safe for consumption, but either it’s not accessible, or there’s not enough of it, or it’s not nutritious enough for maintaining a healthy diet—in which case there’s a lack of food security.

That said, these two issues do relate to each other and in a sense, they can both have the same impact.

In areas where food security is an issue, vulnerable populations may be exploited and sold food that is unsafe, for example, if it’s prepared in unsanitary conditions. Or they might simply have no other choice than to consume the only food they have access to, even though it might not be the safest option (meat that is past due or fresh produce cultivated in contaminated water, etc.).

A lack of food safety measures (which can occur in countries where food security might not be seen as a primary issue) can ultimately lead to food scarcity. Not only do consumers often throw away food due to the fear of food poisoning (or uncertainty regarding best before dates), but large-scale recalls result in many food products being destroyed, which contributes to food waste.

Food safety and food security complement each other, and both are indispensable in the fight against hunger. Both should also be properly implemented to ensure food sustainability. So, while food security often involves political aspects, food safety can be addressed with a digital platform that incorporates various measures to increase food safety, such as compliance monitoring from all supply chain partners, allergen declarations, product lifecycle management (PLM), product traceability and so forth. For example, sales of private label products are growing in the grocery industry. It’s imperative that grocers have the proper digital tools to ensure all their suppliers are compliant and supply food that is of a high quality and safety. It’s even better when they have the ability to integrate and consolidate all these aspects into one single platform.

Food Logistics: What kinds of changes in packaging are happening to better improve food safety measures?

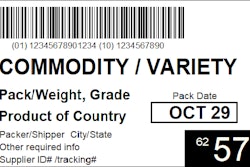

Trejo: Having a robust PLM strategy is a key method of improving food safety. This is crucial for packaging. Every single ingredient in a final product, as well as its origin and the route it took, must be known. For example, while an allergen might not occur in a product, the product itself can be produced in the vicinity of allergens. This must be reflected on a package, but if multiple facilities produce a key ingredient and only some of them have allergens in their facilities, then it becomes extremely difficult to manage package allergen declarations. It’s therefore imperative to have total visibility of all product ingredients and their origins so that such info can be declared. The only way to achieve this is to be able to incorporate all of this into a single digital platform.

Also, the temperature at which food is maintained is one of the most crucial aspects of food safety. Inconsistent and inadequate storage temperatures arising anywhere in the cold chain can cause food spoilage, resulting in unsafe food. It’s therefore critical to have accurate and reliable ways of monitoring temperature in the cold chain. Enter intelligent packaging. This, it seems, is the way of the future, and one exciting new development involves time temperature indicators (TTIs). This could be useful, particularly in food distribution, where a TTI indicator could continuously keep track of the temperature throughout the cold chain. Should the TTI change color, it would indicate that somewhere during the process the foodstuff was compromised by unacceptable temperature exposure for a certain amount of time.

Using TTI labels in food packaging will not only result in better cold chain monitoring but will also reduce food waste and help with better shelf-life management. But an even more powerful approach would be to incorporate things such as TTIs, or any other smart label, with a digital platform that allows superior PLM and traceability. Another way technology is making food safer.

Food Logistics: Please describe some of the technologies implemented to better mitigate risk, improve visibility/traceability and monitor farm to fork along the cold food chain.

Trejo: The Food Traceability rule, based on Section 204 of the FDA Food Safety Modernization Act (FSMA), requires additional traceability recordkeeping for foods on the Food Traceability List (FTL). Important components of the FTL are critical tracking events (CTEs; events in the food supply chain involving the growing, receiving, transforming, creating or shipping of the food) and key data elements (KDEs; information associated with a CTE). While these are great steps toward better mitigating against risk in the cold food chain, it requires a great deal of real-time data gathering and processing.

Fortunately, some great digital platforms exist that consolidate many systems into one and are simultaneously dedicated to the real-time tracing of KDEs and CTEs along the supply chain. This allows real-time item-level and lot code traceability when outbreaks of foodborne illnesses or recalls arise, which is crucial since timing is everything in such cases. The quicker products can be traced and removed from shelves, the better.

It can also greatly reduce the costs involved. There are many past examples from which we can learn: the Westland-Hallmark Meats' beef recall in 2008 that cost nearly $500 million, and the more recent 2021 Tyson Foods recall of nearly 9 million pounds of contaminated frozen chicken. Apart from such astronomical losses, being able to prove that you crossed every T and dotted every I will be the best defense against a lawsuit, should a recall happen. You will essentially have a much better defense if you can prove you exercised “reasonable care.” A digital platform that enables regular automated checks and audits is the only way to do this.

Food Logistics: Going into 2023, what are some things companies should be doing now to better identify risk?

Trejo: Risk can only be identified if you have proper visibility. Whenever you lack visibility anywhere in your supply chain, as well as your locations, then you’re in the dark—or as we at CMX like to say, you’re in constant reactionary mode. All operational, safety and sanitation procedures that are carried out every day must be visible. This is crucial for your own facilities, but it is equally true of all your suppliers. Your own facilities might be fully compliant, but if your suppliers fail in their compliance, their non-compliant products will enter into your operations and could drastically compromise your business. The same goes for Tier 2 suppliers and beyond. You must know whether your suppliers, as well their own suppliers, are also compliant with all your brand standards. Also, it’s imperative that you are well aware of what their standards are, and you should be able to monitor their compliance in real-time (for example, by conducting a desk audit on their facilities).

The only way this can be achieved is by using a fully integrated digital platform. With the sheer amount of record keeping required, there’s just no way to keep a grasp on food safety if you rely on pen and paper-based methods.

It’s even harder when you have to go through an audit, or worse, when a recall happens. Having a lot of data is one thing. The question is, how can that data steer your ship in the right direction? How does it help you to make informed decisions? This is where integrated digital risk management systems are crucial. Any such platform should enable you to use your data to the full so that you can get actionable insights. This is what companies should be doing to better identify risk: invest in technology that will give them visibility over all their operations and localities and which can enable them to use this data to make informed decisions.

Food Logistics: What are some things not addressed above that may be pertinent to our readers regarding food safety in the cold food chain?

Trejo: Perhaps one of the most crucial aspects of food safety, whether specifically in the cold chain or elsewhere, is that of developing a food safety culture. As already mentioned, it truly takes only one employee to compromise the entire chain—for example, failing to monitor or report an unacceptable temperature. So implementing at least some type of food safety training for everyone should certainly be a top priority. This means that everyone in your company must be aware of the risks involved and what can happen when unsafe food is consumed. This should be accomplished by regular training. For example, a digital platform can be used that has easily searchable brand standards guides, policy manuals and standard operating procedures (SOPs) with instructions, images, photos, embedded multimedia and links to supporting content and documents. Such a platform should also conduct regular employee assessments and gather feedback in real-time for continuous SOP improvement and real-time risk management. It’s imperative that such a platform feeds back directly into corporate so that they quickly have adequate intel and agility for innovation. In essence, the time gap between data gathering, policy updates and training should be minimized.

Food safety can become a very personal matter, to which numerous consumers who have lost loved ones due to contaminated food can attest. Everyone should know that they have a role to play, and anyone can report a potential risk if they perceive it.

This is even true of consumers; they also have a tremendous role to play in reporting unsafe food and in making sure they also practice good food safety, such as proper handwashing, keeping hot foods hot and cold foods cold, etc.

At the end of the day, it costs a lot less to be proactive and to prevent food safety incidents, than to try and rectify them. The American foodservice industry loses about $55.5 billion annually due to foodborne illness. Recently, Chipotle paid $25 million for being part of multiple outbreaks between 2015-2018—this is the largest fine of its kind in history. So, be sure to invest in a tried and trusted digital platform to increase food safety—it will save you a lot of money in the long run.

[CLICK HERE to read the article in full].