The medical supply chain is under intense pressure as experts, scientists and manufacturers scramble to develop lifesaving drugs and medical devices to curb the effects of the Coronavirus (COVID-19) disease.

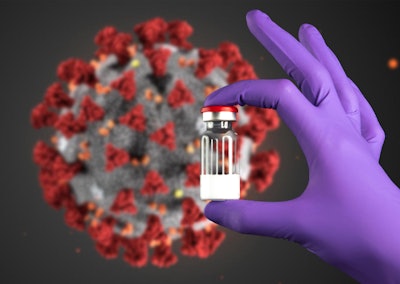

Manufacturers are working around the clock to make ventilators, personal protective equipment (PPE) and test kits to assist in the crisis, while others are entering clinical trials to develop drugs and vaccines that can fight the disease itself. The strain is not just about fulfilling orders and keeping businesses afloat, but saving actual lives, as the world reaches 1 million official cases of COVID-19. But, as we race for a cure, safety still remains an important factor.

The FDA has issued a fast track plan called the Coronavirus Treatment Acceleration Program (CTAP) to help in prioritizing submissions for COVID-19 treatment drugs. Organizations who believe they have medications or drugs that can help fight the disease can submit their products and the FDA will immediately assign an appropriate person to the case upon receipt of the submission. As of press time, the FDA says there are currently 10 therapeutic agents in active trials and another 15 in planning stages.

A one-day response is the organization’s goal pertaining to CTAP submissions as well as a 24-hour protocol review. The FDA provides “ultra-rapid, interactive input on most development plans.” It prioritizes interactions based on the submitted product’s scientific merits, stage of development and identification. The agency will also look for manufacturing alternatives or new sites to avoid supply disruptions for their current uses.

As the pandemic rages on, government regulations have relaxed to speed up the process to get these much-needed supplies and drugs. It is now up to the supply chain partners themselves to uphold strict standards while expediting. Everything from labeling to the quality of supplied ingredients must be held to a significantly high standard to prevent further impediment of these deliveries, as well as further health complications.  Chokniti Khongchum from Pexels

Chokniti Khongchum from Pexels

“Companies continue to follow the same rigorous quality protocols and take the same precautions they always have,” says Chris Harvey, director of recalls at Stericycle Expert Solutions. “Of course, enhancements have been made that are necessary based on the best practices and recommendations outlined by Centers for Disease Control and Prevention and other medical experts. For most companies, that will be enough. But, the challenge may lie among the risks we cannot plan for, like the immense pressure to deliver a greater quantity of safe, quality products with a smaller, stressed, and often, remote workforce.

“What [pharmaceutical and medical device] companies also need to be concerned about is the unpredictable gaps that could result from the reduction in international and domestic inspections. With a pause on international inspections and a reduction with some domestic oversight, we could see a problem slip through or corners being cut that could create product quality and safety issues. Then, even if those issues are identified promptly, companies will have a more difficult time executing recalls remotely and getting high levels of response since the HCP infrastructure may be somewhat compromised,” Harvey adds.

Revamping the supply chain in times of crisis

In the United States, more than three-quarters of medications’ active ingredients come from global sources, according to SpendEdge. With the lowered inspections on imports, it is crucial for supply chain companies to maintain quality. It also puts further strain on the U.S.-based companies, as quarantines worldwide have reduced the number of exports.

Supply chain providers in the pharmaceutical field are expediting ventilators, PPE and COVID-19-fighting drugs. But, how is this possible if they are to maintain the supply of other drugs that many need to stay alive or uphold quality of life on a daily basis?

The phrase “working around the clock” is not a metaphor here. These workers, such as employees at Berkshire Sterile Manufacturing, one of many contracted to develop injections for potential lifesaving COVID-19 drugs, have given up their weekends and nights to join the fight.

Andrea Wagner, senior vice president of Berkshire Sterile Manufacturing, spoke to Supply & Demand Chain Executive (SDCE) and revealed that while maintaining production under Current Good Manufacturing Practice (CGMP) regulations, many of the employees have volunteered to work through weekends and at night to ensure speedy delivery of the injections.

"We have scheduled weekend work while we accommodate these therapies," says Wagner. "BSM has been approached to fill new therapies for the Covid19 virus by currently three different companies. We formulate, sterile filter, fill in isolators, and perform testing for release."

Meanwhile, Protolabs is contracted to supply components for testing kits that can help detect the presence of the virus in an individual. Diagnosing is essential to to help the patient as well as to know to isolate them to prevent further spread. The lab prioritizes these orders by waiving the expedite fee and implementing internal protocols that ensure COVID-19 components are first concern within the organization. Like many others focused on a similar outcome, Protolabs has been declared an essential business.

Protolabs

Protolabs

“However, we know there are many other dependencies in the entire supply chain of a final COVID-19 kit, and so we can only impact what is within our own control. While we manufacture individual components, we do not assemble or distribute finalized kits,” she continues. “Protolabs is seeing an influx of orders for medical components that will help fight COVID-19, including test kits. Protolabs has over a thousand mills, presses, printers and other equipment that enable us to service large amounts of orders at once. Since Protolabs’ manufacturing is done in house, not brokered out, we’re able to provide the quality and consistency (both in the parts and in turnaround time) that is so vital to this cause.”

Like many other industries throughout the entire world right now, a large number of workers in the pharmaceutical supply chain who do not need to be hands on and are more geared toward organizing orders and controlling logistics have been cleared to work from home. Other facilities are minimizing the number of employees in the building at one time, creating different shifts to help keep staff safe.

Argonaut, another lab supporting ingredients for therapeutic drugs for COVID-19, focus on keeping its supply chain strong to provide anything that could be needed for diagnostics or research in addition to providing distribution for detection-focused ingredients. A variety of protocols are in place to ensure distribution can remain strong while keeping employees safe.

“As reported, there is a lack of testing kits available for COVID-19,” says Eric Blair, chief commercial officer of Argonaut Manufacturing Services. “Argonaut is working with governmental bodies like the CDC and BARDA and companies around the world to provide manufacturing and global distribution for companies whose kits can be used in centralized labs as well as other companies who are bringing to market point-of-care kits and detection units at hospitals or field-based units for COVID-19 diagnostic detection.

“Argonaut has the expertise and capacity to serve these clients in their time of need. Additionally, we are keeping our client’s supply chain strong to manufacture and deliver their products that may be used in diagnostics, research or therapeutics. It is a critical role that we are serving to not only build COVID-19-oriented products, but also to ensure the continuity of supply of the research, diagnostic and therapeutic markets we serve.”

As the pharmaceutical supply chain attempts to strengthen in this time of need, many believe the future will see a variety of therapeutic drugs that can help with the symptoms of the COVID-19 as well as a possible vaccine and increased availability of testing kits. Many eyes will be on the supply chain in delivering these sought-after products.