Robots can put together cars just fine, but less ordered tasks still leave them stumbling. Recent advances have allowed robots to pick up hard objects in unstructured environments, but ask one to pass you a bag of bananas and things get difficult: the fruit varies in shape, it moves within the bag, and it’s delicate.

The online grocery retailer Ocado is trying to change that. It already operates several large and heavily automated grocery warehouses. But all of its goods are ultimately picked by humans, because robots can't handle the wide variation in size, shape and structure among the 48,000 different products it sells.

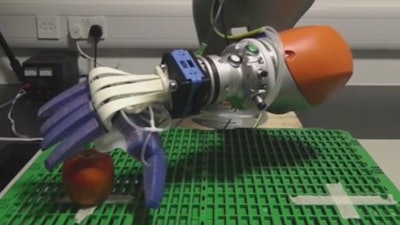

Now, working with a number of universities, its robotics team has taught a soft gripper hand attached to the end of a robot arm to carefully pick up foodstuffs such as apples and bags of limes. Ocado's Alex Voica says that the device responds to changes in the shape of an item throughout the act of grasping, leading to “carefully choreographed movement of the hand in relation to the object.”

The system is also designed to identify specific contact points on the objects, then close around them like a human hand. The idea is to minimize the amount of bruising inflicted on fruits or vegetables.

The company has some problems to solve before it uses the devices throughout its warehouses, but hopes to use them commercially “in the near future.”

Read more about Ocado’s robotics work HERE.