Even before the pandemic, the cold chain infrastructure landscape was rapidly evolving -- e-commerce was on the rise; an increase in frozen food demand was driven by health-conscious consumers; and facility requirements were changing. Changes in behavior due to the pandemic caused panic-buying, accelerating these trends in 2020. As a result, cold storage was one of the fastest-growing parts of the sector. Since speculative development of cold storage facilities has been limited, however, the market must accelerate its response and ramp up construction to meet the new demands.

Because cold chain facilities are more expensive to build and maintain than dry storage warehouses, understanding the special considerations involved in building these facilities is critical. Owners should commit to a project delivery method such as design-build or at a minimum design-assist, which engages the entire team as early as possible during concept planning. This sets the stage for a rigorous pre-construction phase that weighs multiple options and accounts for many variables. Given the expense of refrigeration, having a contractor-led design-build process (in which the contractor weighs in early on various engineering scenarios) can improve life-cycle costs for the facility, decrease service life energy usage, achieve simpler maintenance and result in a fast-track delivery. A guaranteed maximum price contract can also help manage project costs, as well as allow construction to start while more complex engineering and design are still being completed.

Locations and building types are evolving

Many factors must be considered when determining where to build cold storage facilities, and how these buildings are constructed is consequently changing. Owners of large facilities often look to build on sites that are close to manufacturing locations or close to where food is grown and harvested. Considerations when choosing a location for these facilities include access to interstates, site grades and a building area that can accommodate the additional structural requirements of cold storage facilities.

On the consumer delivery end, the “last mile problem” often governs where warehouses are sited. Redevelopment of existing buildings in urban/regional locations, which can meet the demand for tighter turnaround, is one solution being explored. To achieve hyperlocal distribution points, some large grocers are investing in micro-fulfillment centers. As small as 10,000 square feet, these thoroughly automated facilities support delivery to customers within hours of an order receipt. Like larger distribution centers, micro-fulfillment centers are candidates to take over vacant retail spaces.

One thing almost all modern cold storage facilities have in common is the need for tall volumes since automated storage and retrieval systems (AS/RS) usually operate in vertical spaces. This dovetails well with the fact that building “up” reduces a building’s footprint and is a logical way to use tight urban lots and reduce real estate costs.

When looking to repurpose an existing structure, the first task is to complete a review—including an in-person assessment—of the space. The team should examine the building’s load capacity, the condition of its floor slab and the ability to retrofit the structure with modern vapor barriers. Picking and packing in vertical spaces involves many interaction points, so exact ceiling heights and system layouts must be achieved. To identify issues that are not obvious using visual inspection alone, technological tools such as 3D laser scanning can help capture accurate as-built conditions. This aids in identifying potential clashes with newly designed elements, or it can even lead to early discovery if the site is not a viable candidate for redevelopment. Environmental assessments are a good idea if there is a possibility that the site’s surroundings have low air quality or other environmental risks. Traffic assessments will also be important in any non-industrial zone.

Availability of labor is a critical consideration; the complex systems that must be installed in a cold-storage facility require multiple teams of skilled construction workers. Several factors can make acquiring this labor difficult. Storage and distribution facilities being built in zones not previously used to such a market may not have attracted workers to the area. Moreover, there has been a long-standing industry-wide workforce shortage, which has been exacerbated by the disruptions of the pandemic. For the same reasons that labor may be difficult and expensive to procure in zones that have not typically seen warehouse construction, specialized equipment and materials may be hard to source. Teams are also faced with meeting sanitary design requirements, including those brought about by the Coronavirus disease (COVID-19), such as a need for sanitary stations and new entrance/exit configurations (routing personnel in one door and out another).

Specialized building needs

A few of the specialized building elements that drive up costs for cold storage facilities are an insulated building envelope; underfloor heating systems (which prevent soil below the building from freezing); and thermal control systems at building openings. Spaces with multiple temperature zones must be established, and since cold, hot, dry or humid conditions matter—greatly—when it comes to storing food, facilities must be tailored to local climates. Sophisticated control systems may be needed to maintain optimal conditions.

In any automated facility, AS/RS system components, including machinery, racks, conveyors/tracks and controls will dictate design decisions from the ground up. Preconstruction activities should involve addressing a complete checklist of considerations to guide system selection and arrangement.

The ROI of other specialized construction procedures for cold storage facilities should be weighed. For example, investing in jointless floors may be worthwhile, as these floors can ensure smooth movement of automated equipment in a finished facility. Conversely, time and money might be saved by using standardized units and prefabricated parts.

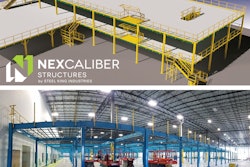

The newest types of cold storage facilities may not look like traditional buildings at all. Rack-supported buildings consist of an independent storage rack system that not only serves the AS/RS but forms the structural system of the entire facility. Walls and roofs are put in place as a “skin” after rack construction.

Complex equipment and regulations

Cold storage interiors require advanced refrigeration equipment. Refrigerant type and refrigerant charge type must be decided upon early. Liquid recirculation systems are being replaced with more modern options. Systems using hydrofluorocarbons (HFCs) are being phased out and low-charge ammonia-based systems, which are more ecofriendly, are especially popular alternatives. Carbon dioxide refrigerants and hydrofluoroolefins (HFOs) are other options.

Off-site assembly of refrigeration units is also a trend. These modular solutions arrive on the jobsite ready to install and are generally available in various capacities and with multiple mounting configurations. They offer a range of operating temperatures and utilize non-hazardous refrigerants.

Refrigeration options should be evaluated for how well they satisfy product-specific requirements, such as the item(s) being handled, required temperature ranges, length of product storage and logistics of moving ripening foods from one chamber to another. But, they should also be evaluated according to how well they conform to overall building requirements. For example, rooftop penthouse refrigeration units can save interior space compared to indoor ceiling-hung units; conversely, where rooftop space is limited, ceiling-hung units may be a better solution.

Rack-supported distribution centers pose a special challenge for refrigeration systems. Temperature stratification can occur in the finished facility, with outdoor air temperature and distance from the cooling source(s) often causing temperature variance in the vertical space. These conditions must be calculated and designed for. Installation of refrigeration systems also occurs differently in rack-supported buildings compared to traditional structures. Refrigeration components must be installed as the building is erected, since space is constrained in the completed structure and access is limited.

Not only are refrigeration systems complex in themselves, but they are energy intensive. As part of preconstruction planning, the project team should assess site utilities and infrastructure for their ability to support the high energy demand. The design and construction team must optimize overall facility energy efficiency to control eventual operating costs.

The many complexities of cold storage facility construction require the design team to make an enormous number of detailed decisions. In addition to these, design and construction should proceed with an eye toward being flexible in terms of future expansion or convertibility of the facility. For example, future needs may require changing the temperatures of various chambers from their original design intent.

As trends shift from in-store purchasing to online purchasing and consumers seek out more fresh and frozen foods, the demand for cold storage warehousing and distribution will continue to increase. This creates a great opportunity for development and construction of such facilities, but the entire industry must take an organized, systematic and knowledge-based approach to meet the challenge successfully.