As emerging companies grow, they find the need for automation in their end-of-line processes. Automation is essential for all brands seeking to drive down per-unit costs and streamline their workflows so they can remain competitive in their respective markets. When it comes to automating case packing processes, emerging brands share a unique set of needs. Here’s why.

1. They are typically smaller and have less experience with automation.

The idea of automating existing processes can appear prohibitively complex and expensive to an emerging company, particularly since the company may anticipate growth that could quickly outpace the abilities of the newly purchased automation equipment. They need strategically engineered automation processes that deliver both a quick return on investment and the ability to rapidly scale upwards using the same equipment.

2. They may offer new or unique package designs to attract customers.

Emerging brands often include creative packaging as a competitive edge to attract customers. Automating this type of packaging requires machines with robust, flexible programming and hardware to handle imaginative packaging designs.

3. The brands may have limited engineering staff to integrate separate units.

Ensuring that multiple pieces of end-of-line equipment work in synchrony and on the same platform requires significant engineering. Emerging brands often do not have the staff or the bandwidth for this type of process, and thus must delegate it to the manufacturer of the case packing equipment. The manufacturer would need to work with the brand to deliver a turnkey solution that is fully integrated with the company’s existing infrastructure and whose parts work together.

4. They may have a small and/or unskilled staff of maintenance crew and machine operators.

A smaller workforce often means emerging brands have thin maintenance staff, as well as machine operators without the requisite skill set to run complex, automated machinery. To address this need, emerging companies require high ease-of-use and a short time-to-proficiency in training their operators and technicians. The machinery should largely require tool-free adjustment. Furthermore, the case packing equipment manufacturer would need to provide troubleshooting, remote support capability, and a team of technicians for remote support if needed.

Case packing technology

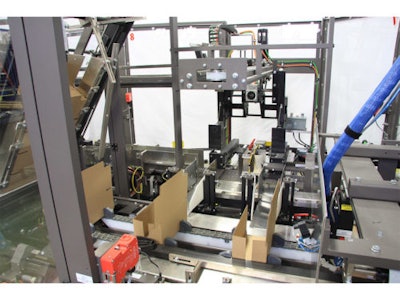

Case packing machines and systems are a core part of a brand’s end-of-line process. These machines can automatically construct and pack cases, preparing products for sale and distribution. This requires that the new machines and processes be integrated with the rest of the production line workflow to correctly identify and place products.

Case packers can pack individual items together as a unit. Different designs assemble and fill cardboard boxes, seal and label packages and more. These systems vary depending on the type of industry and process line they are part of and can perform custom packing operations such as top-loading and side-loading.

Supporting the needs of emerging brands

Case packing technology improves brands’ bottom line by automating processes relating to folding, packing, gluing and taping cardboard boxes. Systems designed for emerging brands’ specific pain points address their issues in a number of ways.

Implementing the appropriate level of automation. Because of its flexibility, case packing technology should be scaled to the appropriate size for the brand’s needs. The manufacturer should help determine this scale based on throughput and the brand’s anticipated rate of growth, allowing the brand to scale upwards as it grows. This is critical to ensuring the brand sees a satisfactory return on investment as it introduces new products to the line.

Integration with existing systems. The manufacturer of the case packing machinery should provide full end-of-line solutions for brands with limited engineering capacity to tie the entire system together. The new technology should come with full project management to ensure the system operates smoothly both between its separate pieces and with the company’s own processes.

Design and changeover flexibility. Companies with novel packaging concepts should be able to easily program the machine to create highly-customized package designs that will appeal to customers and set the brand apart. Changeovers should be able to be accomplished quickly.

Quick to commission and service. For emerging brands time to market is crucial, and few have the bandwidth for extended lead time for delivery and commissioning of equipment. And for most, having access to a remote support team that can assist when help is required is necessary.