Walk into any supermarket on a summer afternoon, and you’ll feel it: the unmistakable chill of cold aisles humming with industrial-scale cooling systems. That crisp air flowing from rows of humming coolers and freezers keeps food safe and fresh, but it comes at a hefty cost. For the average 50,000-square-foot supermarket, annual energy bills can exceed $200,000.

The grocery industry already runs on razor thin profit margins, averaging 1.6% after taxes. As energy prices rise and extreme heat becomes the norm, energy costs are only increasing, creating more of a squeeze. Yet many supermarket operators are overlooking one of their biggest opportunities to cut costs: improving the efficiency and maintenance of their refrigeration systems.

Commercial refrigeration systems consume more electricity than any other equipment in supermarkets, accounting for 40-60% of total energy use, but emerging technologies and smarter refrigeration management strategies now provide a clear path to increased efficiency and savings. When combined with a broader energy management strategy, these benefits can be realized at an even greater level.

The true cost of refrigerant leaks

A typical supermarket refrigeration system leaks approximately 25% of its refrigerant annually, resulting in about 1,000 pounds of refrigerant loss per site. These leaks often go unnoticed until performance dips or replacement costs spike, but every pound of refrigerant that escapes into the atmosphere erodes both energy efficiency and the store’s bottom line.

There are also environmental impacts to consider. Refrigerants with a high Global Warming Potential (GWP), such as R-404A, carry warming effects nearly 4,000 times greater than that of carbon dioxide. In other words, releasing just one pound of R-404A into the atmosphere has the same climate impact as releasing 4,000 pounds of carbon dioxide. These refrigerants trap far more heat, making even small leaks a major environmental concern. Although phasedown mandates are in motion, many stores continue to operate systems using these legacy refrigerants that are liabilities for energy performance.

Reducing leakage, replacing refrigerants

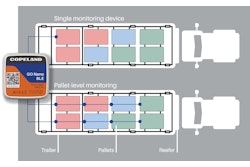

Modern leak detection systems now enable supermarkets to identify and respond to these refrigerant losses in real-time. Distributed pressure sensors placed along refrigerant lines can alert operators the moment pressure drops, even before cooling performance noticeably declines. In recent deployments, integrating these sensors with industrial automation controllers and building management systems reduced refrigerant leakage by up to 50%.

Leak prevention is a critical first step, but swapping out high-impact refrigerants adds another layer of savings and system improvement. Transitioning from high-GWP gases like R-404A to alternatives such as R-448A can reduce direct emissions from fugitive leaks by approximately 70%. When paired with active leak monitoring, supermarkets can cut refrigerant-related lifecycle emissions by more than 90% without requiring a full equipment replacement.

A smarter energy strategy

Refrigeration may be central to supermarket operations, but it’s only one part of the energy equation. The broader infrastructure behind the scenes, from electrical systems to on-site power generation, has a direct impact on operating costs. With wide rooftops and open parking lots, supermarkets are in a strong position to take advantage of solar energy and reduce their reliance on the grid.

Flat, unobstructed rooftops can support large-scale solar photovoltaic (PV) systems, while expansive parking lots allow for additional capacity through solar carports. A rooftop PV array alone can offset 20–35% of annual electricity consumption. When paired with a microgrid controller and battery energy storage system, this setup can reduce imported grid electricity by up to 35%, depending on site location and system size. In a study modeled on stores in Baltimore, rooftop PV systems combined with large parking-lot arrays reduced grid electricity usage by 47%, nearly halving operational carbon emissions and generating substantial long-term savings.

To improve energy performance at the facility level, supermarkets should start by addressing power quality issues, specifically through harmonic filtering and power factor correction. Harmonic distortion happens when equipment like refrigeration systems and LED lighting interferes with the smooth flow of electricity. Installing active harmonic filters helps shield equipment from electrical damage, boosts overall energy efficiency, and lowers ongoing maintenance expenses.

Power factor correction happens when a store’s equipment draws more power than it actually uses (a problem known as low power factor), putting extra strain on the electrical system. Utilities often charge more for this inefficiency. By installing correction equipment, such as capacitor banks, stores can reduce these hidden costs and make better use of the electricity they’re already paying for. Together, these improvements protect equipment, reduce waste, and lower energy bills, often with a relatively short payback period.

Rethinking energy efficiency going forward

With margins under pressure and regulations evolving, supermarkets can’t afford to overlook refrigeration. It’s not just a line item on the utility bill; it’s central to how these stores run every day. By tightening up system efficiency, generating more of their own power, and managing refrigerants proactively, grocery operators can strengthen performance across the board. These steps reduce costs today while future-proofing operations and ensuring stores are ready to meet the demands of their customers well into the future.