It’s widely accepted that automated guided vehicles (AGVs) help businesses save money. What everyone really wants to know is – how much and how quickly?

To answer these questions, most people come up with a hard number that weighs the total cost of the AGV system against the labor and manual equipment it is able to replace. This is a good place to start, but it doesn’t tell the whole story. If you make your decision based on this number alone, you’re probably underestimating ROI.

Companies tend to overlook basic ROI calculations and the operational and financial benefits. Some of these benefits are quantifiable and can be estimated based on historical data. Other benefits are less immediately tangible and must be evaluated with future business goals in mind.

Immediate financial benefits of AGVs

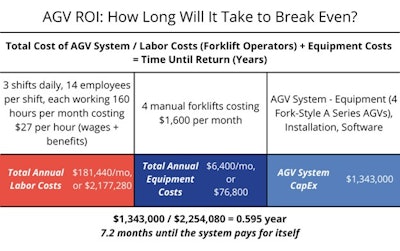

A basic calculation for a greenlight project ROI might look something like this hypothetical example, which is based on replacing four manually operated forklifts with fork-style AGVs (aka driverless forklifts).

Murata Machinery USA, Inc.

Murata Machinery USA, Inc.

Already, you start to see a favorable ROI, but there are additional hard savings still unaccounted for, such as reduced workplace accidents.

Reduced workplace accidents. Driverless forklifts eliminate opportunities for human error, which makes them safer than conventional forklifts. According to National Security Council data, conventional forklift accidents are a leading cause of work-related deaths and severe injuries. The average forklift injury causes 16 days away from work, which significantly impacts productivity and employee retention in already labor-strapped industries.

Fewer materials damaged in transport and handling. Forklift mishandling is the leading cause of pallet damage. Pallet damage leads to expensive material losses, operational disruptions and equipment problems. Automated forklifts don’t make the same errors in judgment that human operators do and are associated with lower rates of pallet damage.

24/7 production capabilities. Like other forms of automation, AGVs make it more affordable to run around-the-clock production. They also consistently achieve uptime rates as high as 99%. This allows an AGV system to accomplish more than the conventional system it replaces.

One more hard financial benefit to note – this calculation presents ROI as a short-term Year 1 consideration. In reality, the benefits are longer lasting. AGVs are depreciable assets while human employees are not. AGV systems last for years and require minimal capital expenditure after the initial investment is made, so value increases year over year when properly serviced and maintained.

Click here to hear more about AGVs and human worker collaboration:

Long-term operational benefits of AGVs

AGV technology is also future friendly – it provides an ideal high-value entry point to full automation and paves the way to easier and more efficient facility updates down the road.

System flexibility. AGV systems are modular by nature, and available with multiple types of navigation technology. This allows facilities to start with a small number of vehicles and systematically scale up as needed. AGVs can be easily integrated into both new and existing facilities, and support a high level of reconfiguration as operations grow and change.

Space savings. Depending on the type of AGV, vehicles can interface directly with other systems, maneuver in tight spaces and underneath or around other equipment and perform in close proximity to people. This flexibility saves businesses money through space optimization and the ability to create unique transportation routes.

Protection against the skilled labor shortage. The skills gap hurts industrial productivity and profit margins, and there’s no sign of it letting up. AGV systems reduce the overall volume of workers needed. They also transport hazardous materials and work in demanding, harsh environments, freeing people to work in more favorable settings.

Integration with other automated material handling systems. AGVs can interface directly with other automated solutions, including automated storage and retrieval systems (AS/RS) and goods-to-person workflows.

AGVs: An entry point to automation with fast returns

Automation is a foundational aspect of the digital transformation, but many businesses are caught at the crossroads, not knowing where to start or how to make the wisest investment. Because of their quick returns, scalability and flexibility, AGVs are an excellent place to start. AGVs have been in use for decades – they’re a proven technology that has benefited from years of continuous innovation. Today’s vehicles come in many sizes and custom configurations to accommodate a wide range of load size and handling needs. Businesses have plenty of options for building a reliable AGV system that strikes the right balance between price and performance.