From goat milk to horse meat, there have been many discussions about traceability and product recall sparked by these and other food safety crises. Food and beverage manufacturers, along with their retail customers, have found themselves under increased pressure to improve visibility into their supply chains to allow them to properly track food from farm to fork.

To help them address these concerns, manufacturers are turning to traceability and product lifecycle management approaches to efficiently bring products to market and manage all of the data linked to their movement through the value chain.

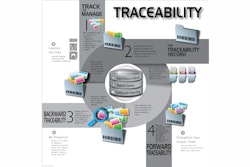

Traceability

In order to prevent situations like food recalls, retailers must insist that everyone in the supply chain—not only their suppliers, but also their supplier’s suppliers and so on—collaborate in order to understand where and how goods are coming into the supply chain, from end-to-end.This needs to be strictly audited to enable any incongruences or inconsistencies to be identified, investigated and addressed.

However, most companies today do not have the ability to manage inventory across an extended network of suppliers, distributors, manufacturers and producers. As a result, a lack of visibility into the supply chain has enabled such occurrences as the illegal substitution of horse meat in the food supply chain to arise, and continue unchecked.

The food supply chain is incredibly complex due to the increasingly global sourcing of materials and ingredients, with many parties handling them through a long chain of custody. Many blind spots exist in this process, resulting in loss of control.

Processed food presents even greater complications for traceability, as each individual ingredient needs to be tracked, taking into account the fact that ingredients come from multiple suppliers, each with their own practices, disparate systems, protocols, data formats and coding structures, in countries with different regulatory requirements.

Cloud-based traceability applications can capture data from all of these sources, translate it into common formats and integrate it into appropriate applications for processing, providing farm to fork supply chain visibility.

Source level data, such as unique animal identification, date, farm, etc., is captured electronically and is immediately visible to all supply chain participants. Additional data is added at each touch point—for example, what cuts of meat have been produced from that animal and where each of those cuts are then sent. Additional data about other ingredients is added as the meat is combined with other products, providing a complete ‘genealogy’ of the finished product.

Cloud technology has broken down barriers to sharing data across extended trading networks, yet there are still psychological barriers to collaboration, based on fears about security and competitive advantage. However, in the interests of human health and social responsibility, it is imperative that all participants in the food supply chain work collaboratively and contribute their production and manufacturing processes as workflow elements in the cloud.

Product recall

On average, the cost of a product recall is $10 million [Source: Recall Executing Effectiveness: Collaborative Approaching to Improving Consumer Safety and Confidence, conducted by Deloitte on behalf of the Food Marketing Institute (FMI), the Grocery Manufacturers Associate (GMA) and GS1 U.S., May 2010]. This does not account for financial impacts ranging from damage to brand reputation and lost sales, nor the possible human cost of failure to recall unsafe product.A 2012 JDA Software survey of 130 consumer packaged goods, life sciences and food and beverage companies found that almost 72 percent of senior supply chain and operations executives are not completely confident in their organization’s product recall and traceability capabilities.

In addition, the survey results also showed:

• Coordinating recall issues with suppliers and distributors is a real concern for almost 70 percent of executives surveyed.

• Less than 20 percent have deployed traceability technology solutions to support fully automated trace and recall processes.

• Almost one-third of executives were most concerned that their ineffective ability to trace items would have a negative financial impact on their company. Almost 25 percent of them also cited negative brand reputation as a pressing concern.

• Eighty-six percent are worried about their financial liability if something goes wrong with a product recall process.

In addition to the ability to effectively isolate ‘rogue’ product in the food supply chain, it is critical that the location of that product can be accurately pinpointed, allowing product to be recalled from warehouse stock, warehouse pick, transportation, store stockroom and at point of sale.

In a nutshell, an effective recall relies on knowing exactly what product to recall and exactly where it is in the supply chain.

The key to both traceability and recall execution is the adoption of technology to automate the processes and facilitate collaboration across suppliers and distributors.

If everyone works collaboratively in a single cloud-based system, bad ingredients into the food supply chain can be quickly identified, if not prevented, and recalls of affected products can be rapidly and cost-effectively conducted. ?