The clock is ticking. As a shipment of organic strawberries travels en route from Spain to Germany, every minute counts. As the truck crosses borders, questions loom: Were the berries kept at the right temperature? Can their organic certification be verified instantly? For food logistics managers, these scenarios aren't hypothetical – they're daily challenges that can make or break a business.

The TRICK project, an EU initiative with $8 million in funding, focuses on sustainability and creating a circular economy in the food and textile industries. The initiative aims to tackle the issues in food transportation that contribute to $143 billion in food waste annually. As part of this goal, TRICK is developing a reliable, affordable and standardized platform for data collection, secured by the Quadrans blockchain. As TRICK continues to gain adoption, it’s creating a potential lifeline for an industry drowning in manual documentation processes and plagued by transparency issues.

At its core, TRICK leverages a blockchain-based platform for food companies to connect product data securely. It sounds technical, but for logistics professionals, it translates to real-world benefits: faster customs clearance, easier compliance checks, and the holy grail of supply chain management – true traceability.

Blockchain technology addresses key pain points in supply chains that existing systems have struggled to solve. In an industry where products change hands multiple times across borders and jurisdictions, blockchain offers a single source of truth that can be shared across all parties without requiring a central authority. This approach enables detailed, end-to-end tracking of products and their associated data throughout the entire supply chain.

For food logistics managers, blockchain's benefits are both practical and transformative. First, it ensures data integrity – once information is recorded, it cannot be altered, significantly reducing the risk of fraud or accidental changes. Second, its decentralized nature enables all supply chain participants to access the same real-time information, fostering unprecedented transparency. Lastly, blockchain-based smart contracts can automate compliance checks and certifications, streamlining paperwork and accelerating processes. These features uniquely position blockchain to address the traceability and transparency challenges that have long plagued food supply chains.

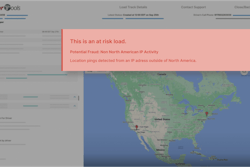

However, as any seasoned logistics professional knows, implementing new technology comes with growing pains. The TRICK project initially faced compatibility challenges when connecting different blockchain systems – a familiar headache for anyone who's tried to integrate new software with legacy systems. Next, the TRICK project team and Quadrans blockchain had to solve another thorny technical issue: how do you maintain iron-clad security when information needs to flow seamlessly between private and public systems?

Verifying the authenticity of food products and combating counterfeiting is a costly burden on the industry – both financially and reputationally – and ensuring the integrity of product data as it moves between systems is paramount. The solution to TRICK’s technical hurdles came in the form of verification technology that certifies data sources and tracking events before they are stored on the blockchain. For food logistics managers, this means being able to trust that the information they're seeing, whether it's about organic certification, temperature logs, or customs documentation – even when that data has traveled across multiple systems – is wholly accurate.

The results are compelling: initial tests demonstrate the system's capacity to manage the intricate network of certifications, audits, and compliance checks integral to modern food logistics. Customs clearance processes, traditionally a significant bottleneck in international shipments, show marked improvement in efficiency. In a sector where time directly impacts profitability, food quality and waste, these gains in efficiency represent a substantial advancement. The potential for reducing delays and streamlining operations offers tangible benefits that could reshape how the industry handles cross-border shipments.

But perhaps the most striking aspect for food logistics professionals is the potential for substantial cost reduction. By shifting complex computations off the main blockchain, the system has demonstrated significant decreases in processing costs. In an industry where profit margins are often razor-thin, this level of cost efficiency could redefine operational strategies and competitive advantages. The ability to maintain robust verification processes while simultaneously cutting expenses presents a rare opportunity for companies to enhance both their bottom line and their supply chain integrity.

The implications extend beyond operational efficiency and costs: as consumers increasingly demand transparency about their food's journey, this technology offers a way to provide that information credibly and cost-effectively. Instantly verifying authenticity claims or provide a complete temperature history for sensitive shipments – all with the click of a button, and all backed by a system that makes data tampering virtually impossible.

Small and medium-sized enterprises in food logistics, typically excluded from advanced traceability solutions due to cost barriers, stand to gain significantly from this innovation. The TRICK project aims to democratize access to sophisticated supply chain technology, enabling SMEs to implement robust verification systems without substantial investments in IT infrastructure or specialized blockchain knowledge. This shift could reshape market dynamics, allowing smaller players to compete more effectively with larger, established companies in terms of supply chain transparency and efficiency, ultimately enabling more produce to safely make its way into the hands of their consumers.

As the project moves towards full implementation, food logistics professionals should keep a close eye on its progress. The challenges it's tackling – interoperability, scalability, security, cost-effectiveness, and transparency – are universal in the industry. Its successes will provide valuable insights for anyone looking to enhance their supply chain transparency and sustainability.

The road ahead isn't without its bumps. Questions remain about widespread adoption, integration with existing systems, and the inevitable learning curve of new technology. But for an industry constantly pressured to do more with less, to be faster, more transparent, and more efficient, the potential benefits are too significant to ignore.