To the untrained eye, they’re simple barriers. However, ingenious engineering and high-grade materials lie beneath the surface of today’s bulkheads and curtains.

They’re ubiquitous and underappreciated.

Passive temperature regulation has quietly supported cold chain for decades, even as advances in telematics or active refrigeration units dominated the headlines. Despite being overshadowed by these more high-profile technologies, curtains and bulkheads have played a crucial role in foodservice distribution and have evolved in their own rights.

From materials that do heavy lifting on a granular level to the minute details that enhance insulation, these solutions have not only kept perishables safe for public consumption but have also helped food distributors stay compliant.

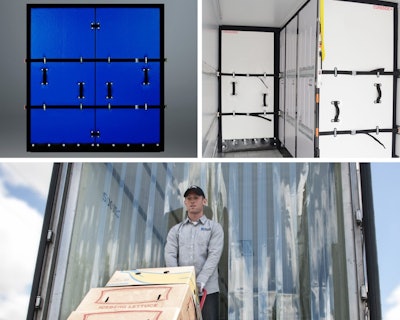

Bulkhead insulation

Today’s bulkheads maintain temperature zones for your perishable cargo with high performance materials like closed-cell foam and 18-ounce vinyl to create impenetrable, moisture-resistant surfaces. Modern innovations like an added layer of antimicrobial protection further protect the surface so that no foreign microbes can take hold and flourish.

Common wear and tear from contact with rough, non-skid trailer floors has been eliminated, as updated bulkhead models now come with a UHMW skid guard featuring no-catch, recessed hardware that is durable and long-lasting.

To bolster the all-important seal, the most advanced bulkheads surround that low density foam with ballistic nylon, one of the strongest and most abrasion-resistant materials commonly used in military applications. Combined with replaceable perimeter gaskets and hinges also made from ballistic nylon, an impenetrable seal is made to ensure that temperatures stay stable in their respective zones and prevent air leakage. Reinforcing this seal helps to lower excessive fuel and maintenance costs, prevent product loss, and keeps your operation compliant.

All this effort put into the construction of today’s most advanced bulkheads, combined with the easy replaceability of every component grants them longevity beyond the life of the vehicles they’re installed on.

Center divide systems

To be truly effective, your center divider system should be durable yet configurable to make it easy to set up temporary compartments according to your needs.

By using lightweight, flexible materials like TPO composite as building material, the most advanced center divide systems strike the perfect balance of stiffness, cold temperature impact, and low thermal expansion. Combined with half bulkheads, they keep temperature-sensitive foods safe for consumption and compliance. The final products are ultra-durable, impact-resistant, and recyclable—qualities that go a long way in a high-traffic space.

Top center divide systems of today take efficiency into consideration as well, with built-in recessed airflow channels that assist with the guidance and distribution of precious cooled air inside a trailer.

Like the top bulkheads, the industry’s best center divide systems establish tight seals with the help of ballistic nylon and prevent wear-and-tear from contact with trailer floors using UHMW extrusion and skid guard.

Rear strip door curtains

Though simple in appearance, the real ingenuity in today’s top rear door strip curtains is found in their versatile configurations.

Made from overlapping 18-ounce vinyl or PVC strips that keep dust, wind, insects, and debris out of trailers, the most premium versions of this solution can be custom cut for a door’s specific dimensions and is easily replaceable, down to the individual strips. Different mounting possibilities include positions on rear walls and sidewalls with the ability to be easily moved, removed, pivoted, and swung open or closed like a gate.

Easy, quick access in and out, with the ability to close quickly and securely means that temperatures inside stay stable, energy is conserved, and your cargo maintains integrity.

Cold comfort

Despite their seemingly low-tech appearances, the bulkheads, dividers, and strip curtains of today are made to perform at high levels, thanks to meticulous engineering and use of the most high-quality, durable materials. And while more high-tech solutions grab the headlines, these products play integral parts in the foodservice transportation ecosystem.