Velodyne Lidar, Inc., in collaboration with Seoul Robotics, will demonstrate how its smart, powerful lidar solutions advance automation and safety in manufacturing and supply chain solutions at MODEX 2020.

Velodyne will highlight lidar sensors that can be used in robotics, automated guided vehicles (AGV), forklifts and security applications. Velodyne lidar solutions can improve industrial automation, materials handling, yard management and distribution center operations.

At its booth, Velodyne will showcase the Puck 32MR, a lidar sensor that produces a data-rich image with the ability to detect low reflectivity objects at a range of 120 meters. The sensor is optimized for outstanding indoor/outdoor performance, operating in a variety of light conditions. By combining high-resolution 3D perception with a broad vertical field of view, the Puck 32MR accurately detects crosswalks, curbs and obstacles in warehouse aisles for safe and efficient navigation in roadway, commercial and industrial settings.

Velodyne will also highlight the Velarray, a powerful sensor solution to greatly improve automated safety. Its small, embeddable form factor enables the sensor to be seamlessly integrated into a variety of industrial and robotics equipment. The Velarray produces a robust directional image, day or night.

“As the demands for supply chain efficiency and safety increase and evolve, lidar technology is helping companies vastly improve manufacturing and logistics performance,” said Jon Barad, Vice President of Business Development, Velodyne Lidar. “Supply chain systems need to continue to become smarter and safer, more efficient and further automated. To address these requirements, companies are turning to lidar to play a key role in enabling the next generation of manufacturing and supply chain solutions.”

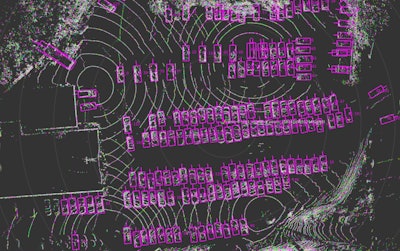

Also at the booth, Seoul Robotics will demonstrate the benefits and applications of Level 5 Control Tower solution, powered by its proprietary AI engine, SENSR, which is optimized and available commercially to process Velodyne’s rich and reliable 3D data. Seoul Robotics uses artificial intelligence (AI) for detection, counting, classification and tracking of objects in real time. It can accurately track the location, coordinates, speed and direction of objects and predict their path, such as vehicles and people at a distribution center or manufacturing and logistics operation.

“As vehicles and material handling equipment are increasingly automated in logistics yards and distribution centers, industry must develop and deploy in parallel a robust and safe operating environment. This will resolve well-known challenges with trucks and equipment, such as blind spots and occlusion, in order to successfully realize the promised efficiency and economy,” said David Han, Seoul Robotics’ Managing Director of North America & Global Automotive. “Level 5 Control Tower equipped with Velodyne lidar enables exactly that – a robust and cost-effective infrastructure-based perception solution that monitors and guides the movement of automated and conventional vehicles within the entire yard – efficiently and safely.”