Hurricanes Harvey and Irma were devastating in their own ways, but their impact on freight followed a typical three-stage pattern.

- Before the storm, forecasts gave shippers time to plan. Outbound rates increased, but goods were rerouted, stockpiled and saved from spoilage.

- During the storm, nothing moved until power, roads, rails and other infrastructure were deemed safe.

- After the storm, emergency supplies came first, followed by van and reefer freight, and then flatbeds with equipment and materials for cleanup and rebuilding.

One thing that distinguished Harvey from Irma is the significance of Houston to the national freight economy. Distribution centers near Houston serve at least six states; after Harvey, some shippers began to supply markets ordinarily served by Houston from hubs in the Southeast, including Atlanta, Charlotte and Memphis. Warehouses in the Midwest were called on to supply the Northeast in order to compensate for freight that otherwise would have come from Atlanta. Many of those warehouses had to supply Colorado and other out-of-the-way markets ordinarily served by Houston.

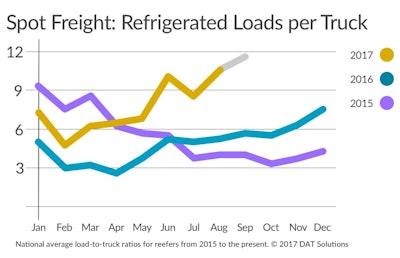

It’s telling that on Aug. 30, when Harvey made its final landfall, the worst truck shortage according to our DAT Hot Market Maps was in Grand Rapids, Michigan. That’s because trucks were being diverted to deliver emergency relief to staging areas like San Antonio and Dallas, leaving shippers in the Midwest scrambling for trucks to move apples, potatoes and other seasonal freight.

The storms tested supply chains, but also showed what a resourceful industry we can be. Many offered equipment and warehousing to organizations like the American Logistics Aid Network. The help is greatly appreciated as the cleanup continues.