Safety and efficiency are more important than ever in today’s food logistics landscape. As food manufacturers face increasing pressure to meet stringent industry regulations, reduce contamination risks, and optimize their operations, plastic reusable pallets have emerged as a vital solution. The shift from traditional wood pallets to hygienic plastic alternatives is transforming how food supply chains operate, offering a cleaner, safer, and more consistently reliable, sustainable way to move goods.

Here's a breakdown of the benefits of hygienic plastic pallets, best practices for their implementation, and what the future holds for food logistics.

Why reusable plastic pallets matter

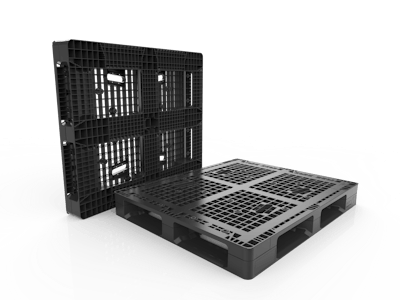

Plastic pallets are revolutionizing food logistics by addressing a key industry challenge: hygiene. Unlike wood pallets, which can absorb moisture and other materials, plastic pallets are non-porous, making them easy to clean and sanitize, significantly reducing the contamination risk across the supply chain. In industries where food safety is crucial, this shift is a major improvement.

Plastic pallets also provide enhanced durability and reusability. A 2017 study by Purdue University compared the sustainability and life cycle costs of plastic versus wood pallets. The research found that while wood pallets have a lower upfront cost, they require more frequent repairs and replacement throughout their life span.

Design features that support cleanliness and efficiency

A critical element of plastic pallets is their design. Features such as smooth surfaces, rounded edges, and the absence of nails or fasteners not only make cleaning easier; they also reduce the risk of damaging products during transport. Open-deck pallets allow for better airflow, which is especially beneficial in refrigerated storage or for items that need to be cooled quickly.

Plastic pallets also work exceptionally well with automated systems. According to a report from World Metrics, around 25% of warehouses globally have adopted some form of automation, with about 30% of these facilities incorporating robotics. The uniform design and durability of plastic pallets make them particularly suited to automated material handling and storage systems, helping companies optimize their operations.

Continued support of FSMA

The Food Safety Modernization Act (FSMA), administered by the FDA, focuses on preventing food contamination across the supply chain, including transportation. FSMA regulations emphasize sanitary transportation practices and foodborne illness prevention, requiring proper cleaning, maintenance, and storage of food-contact surfaces, including pallets.

A new aspect of the FSMA is the Food Traceability Rule, or Section 204, which goes into effect in January 2026. This identifies certain foods and requires additional recordkeeping on these foods as they move in the supply chain. As traceability becomes increasingly important, pallet tracking could increase.

While the FSMA does not specifically mandate the use of plastic pallets, the guidelines support their use given their easier cleanability and trackability.

Reusable solutions beyond pallets

Plastic pallets are just one part of a larger suite of reusable packaging solutions that can enhance food logistics. Products include plastic reusable totes and bulk containers for inbound shipments, as well as plastic corrugated cases that replace fiber corrugated boxes. When these solutions are implemented, they provide a holistic approach to food logistics that prioritizes hygiene and operational effectiveness.

Implementing plastic pallets in food logistics

Transitioning to plastic pallets is a strategic decision that can yield significant benefits, but it requires careful planning and execution. First, it’s worthwhile to assess your specific logistical needs, including the type of goods being transported, storage conditions, and handling methods. For example, plastic pallets used in freezer environments need to withstand low temperatures without compromising their integrity.

Training is another key component of successful implementation. Employees need to be educated on proper pallet handling, cleaning, and maintenance protocols to ensure pallets remain in optimal condition. Taking care of these valuable assets is critical for long term success.

Overcoming challenges in adoption

Like any significant operational change, adopting plastic pallets may face some resistance, particularly from organizations that have long relied on wood pallets. However, the long-term benefits—such as reduced downtime and risk of food contamination along with improved food safety, durability, and cost savings—make plastic pallets a compelling option.

Engaging all levels of the organization in decision-making, from warehouse employees to upper management, is key. Demonstrating the value of plastic pallets through pilot programs and ROI analyses can help overcome hesitation and ensure successful adoption.

The future of plastic pallets in food logistics

Greater adoption of plastic pallets and other reusable packaging solutions is expected as the food supply chain industry evolves. Innovations in automation and smart technology will likely play a major role in the future of plastic pallets. Pallets embedded with tracking technology, for instance, can provide real-time data on their condition, location, and usage patterns, giving companies greater visibility and control over their supply chains.

In conclusion, plastic pallets are transforming food logistics by offering a hygienic, sustainable, and cost-effective alternative to wood that leads to reduced downtime and risk of food contamination. Their design, material selection, and compatibility with automation make them an invaluable asset to maintaining food safety standards throughout the supply chain. As food manufacturers continue to focus on cleanliness and efficiency, plastic pallets will play an increasingly pivotal role in shaping the future of food logistics.