*Sponsored by Edge Impulse*

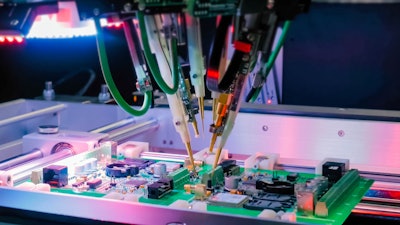

If you can find the bottlenecks that are slowing down your assembly line, you can increase efficiency and productivity. Manufacturing managers, roaming the factory floor, can address workflow impediments, but these supervisors can’t be everywhere at once. Using Edge Impulse's industry-leading edge ML development platform, Advantech developed a smart monitoring system that autonomously flags even tiny delays, providing for precise fine-tuning with less human oversight. The new setup, now in place on a live assembly line, can easily be re-trained to monitor other production tasks.

In this case study, learn how Advantech achieved:

● Increased productivity through the detection of idle time

● More efficient use of managers’ time, refocused on production planning and operations

● Production efficiency improvements through easily deployed video analytics, even by managers with no AI experience