AB Vassilopoulos (AB), a leading supermarket chain in Greece, purchases fresh fish from one of the largest fish farming companies in Europe, which is also based in Greece. The producer harvests fish at its aquaculture facility and transports them 10 km to its cleaning and packing facility. Once cleaned and packaged for retail sale, the fresh (unfrozen) fish is then transported 280 km to AB’s distribution center, and from there, to the chain’s retail outlets.

Temperature is checked by both the fish producer and AB at each stop in the supply chain to determine if pre-defined thresholds are exceeded at that time.

Challenge

Although every effort is made to maintain the cold chain from harvest to point of sale, the highly perishable nature of fresh fish results in losses in the supply chain when temperature is tracked only at specific points. Globally, 35% of all consumable fish and seafood is wasted, and distribution and logistical challenges account for nearly 10% of supply chain losses.

Temperature is measured and recorded manually at each step of distribution, but this data is not shared between producer and retailer. If arrival temperature is found to be within the acceptable range, the fish’s shelf life is assumed to be as expected. Therefore, no corrective actions are necessary. If the fish has not been sold to consumers by one day prior to the “Best by” date, the fish is tossed.

This system does not account for how much shelf life is needed for a good consumer experience, how much shelf life was lost during business steps and how much remains. In short, periodic temperature readings alone are insufficient to tell, on the spot, how many quality hours or days a perishable has remaining. Instead, supply chain partners require increasingly shorter supply chains to ensure consumer trust in freshness.

Because of the uncertainty in handling, the freshness of fish caught on the same day will differ unexpectedly. And, with only periodic temperature monitoring, handlers are unable to take corrective action until after the fact.

Solution

Infratab, Oxnard, Calif., developed Infratab Freshtime, which includes RF sensor tags, software and cloud solutions for constant tracking and tracing of the temperature and shelf life of perishables.

Hardware: Dual RF (RAIN and NFC) temperature and shelf life tags for constant tracking and tracing of perishables in the supply chain. The tags are GS1 savvy, working with GS1 QR and barcodes, data and RAIN readers. NFC smartphone owners need only their phones.

Software: Dashboards for setting up tags, for accessing temperature and shelf life status, inspecting, and confirming handovers; cloud services for storing data, noting incidents, reporting, connecting to blockchains and performing analytics.

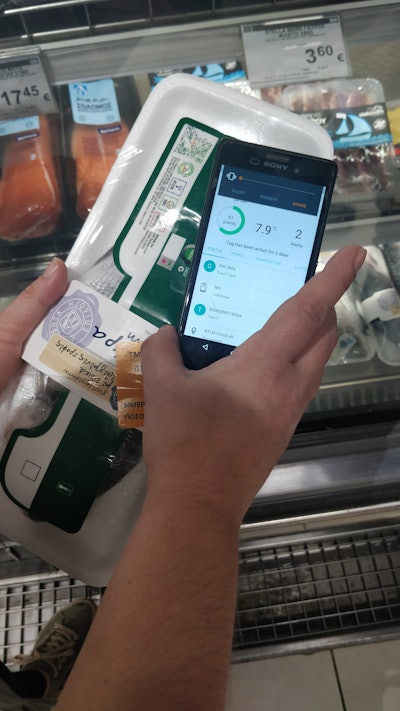

Freshtime tags are placed on individual packages of fresh fish by the producer prior to shipment to AB. Supply chain partners can download the Freshtime Mobile app on their smartphone to control and record starting and stopping, temperature checks, changes of custody, inspections and uploaded pictures of product status.

When the tag is read, the latest status information can be added automatically to the item’s blockchain. However, no app is required for a user to check status. Anyone can check product status using the tag’s on-tag button and display.

Through the Freshtime dashboard, temperature alerts are set to notify specified participants if a threshold has been breached or too much shelf life has been lost. In the case of a breach, the notified user would see a red screen and can then initiate a comprehensive report sent by e-mail to subscribed users.

Results

The project, which was the first of several iterations and expansions of the Infratab Freshtime technology in this supply chain, validated the accuracy of the Freshtime analytical model in predicting shelf life used and remaining for seafood by comparing microbiological evaluations of fish at regular intervals during distribution to those of Freshtime’s predictive model. These evaluations were performed by researchers from the National Technical University of Athens (NTUA), Greece.

The use of Freshtime tags in this supply chain expanded to include the harvest phase (pre-cleaning and packing) as well as the point-of-sale phase (consumer use), as consumers can also access Freshtime’s shelf life and provenance data via their smartphone, if permitted by the brand owner.