The trucking and transportation industry has been plagued by a series of supply chain challenges. The driver shortage. Increased wages. Rising fuel prices. Rising cost of goods. Ingredient shortage. Supplies shortage. Canada-border protests. Increased shipping costs. The list just. Keeps. Going.

But, it’s the driver shortage creating the biggest impact.

In Food Logistics’ July/August 2022 issue, editor-in-chief Marina Mayer talks with several industry experts about the trucking industry’s wins and woes and how, despite continuous supply chain challenges, the transportation sector keeps driving forward.

Here’s an interview with Brian Antonellis, SVP, fleet operations for Fleet Advantage, who details the importance of fusing today’s and tomorrow’s technologies, with excerpts publishing in Food Logistics’ July/August 2022 issue. [CLICK HERE to read the article in full].

Food Logistics: In recent weeks, several motor carriers have announced their intentions to add electric trucks to their fleets. What will the stride toward electrification do the transportation industry? The future?

Brian Antonellis: Corporations and government leaders are facing tremendous pressure from key stakeholders, environmental groups, customers and shareholders to find ways to reduce GHG output from their factories and supply chains. This is now reflected in that an estimated 90% of companies in the S&P 500 provide environmental, social, and governance (ESG) plans and reports to demonstrate how they will reach aggressive carbon-reduction goals. Over the last few years, more corporations and business leaders have taken steps to initiate these ESG plans and goals. Still, more efforts are needed today since the SEC recently issued a proposed rule that would enhance and standardize the climate-related disclosures provided by public companies. Under the proposal, a registrant will be required to adhere to GHG emissions disclosures within qualitative governance disclosures within their annual reports (e.g., Form 10-K).

While the movement toward electrification has received glowing applause and headlines worldwide; its near-term application can only be based on the current path of technological gains.

Heavy-duty trucks remain essential to keeping the global economy running, especially today, as raw materials shortages have severely strained worldwide supply chains and deliveries. Trucks that move goods, medicines, technology products and construction equipment have never been more critical to local, national and international economies.

There has been an increasing amount of press coverage romancing the idea that a plethora of start-up truck companies can quickly revolutionize the industry and deploy a convoy of long-haul trucks built with EV battery technology. They have received their fair share of press coverage during their honeymoon phase. However, these companies have so far failed to deliver on their promise because of a simple fact that EV battery technology remains elusive in its quest to accomplish the realities of balancing battery weight, necessary vehicle range and payload requirements especially for over-the-road Class 8 equipment.

Fleet Advantage believes that the best approach to bridge today’s clean-diesel technology into tomorrow’s alternate energies is by leading with the appropriate ESG strategy supported by strategic industry partners, companies with experience, and heavy-duty fleets that can meet today’s need for transport infrastructure while serving as leaders to the future.

Most Class 8 tractor OEMs are introducing EVs. But even the best ones get only 250 miles per charge and that is not enough for cross-country operations. If you’re running 500 miles a day, the charging infrastructure doesn’t exist. Charging an EV Class 8 in an hour or less is also a bigger challenge than charging a smaller vehicle. Until a national network of truck chargers is created, companies will need to install them in their delivery stations or DCs. On top of the cost of charging stations ($25,000-100,000), an EV typically costs $325,000-360,000, compared to a diesel tractor ($125,000-150,000). Combined with the charging station costs, it would be difficult to make up those upfront expenses over the first five years. However, we are seeing some success with yard tractors and trailers, depending on the industry type.

Food Logistics: What is your company doing to achieve a more sustainable fleet? Please provide press releases if necessary.

Antonellis: Entering the new millennium, few companies across all industries had a watchful eye toward environmental stewardship, particularly throughout the heavy-duty truck transportation industries. However, just a few short years later, governments in many countries began to better understand the benefits that could come from corporations curbing their carbon emissions output, and new greenhouse gas mandates began to take effect by the early 2000s.

Fleet Advantage has pioneered the use of data analytics to help fleets run their operations more efficiently. The company realizes the importance of helping fleets not only comply with the new environmental regulations but serve as model corporations regarding environmental stewardship.

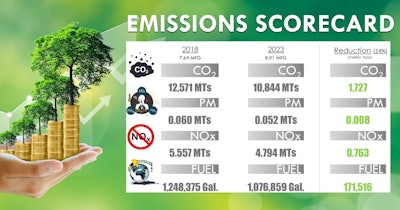

Fleet Advantage was founded in 2008 with the goal of being the future of truck leasing by advocating solutions that would significantly reduce emissions over time. By 2011, Fleet Advantage had begun to make strong recommendations against the use of older-model equipment because of toxic emissions. The company introduced never-seen-before emissions scorecards, and a pioneering replacement program with financial flexibility in mind that made it beneficial to operate newer, clean-diesel engines. This program also helped fleets meet new GHG-1 Federal mandate standards and calculated fuel economy gains at 2.5% MPG and CO2 reductions.

Fleet Advantage’s leadership and focus toward environmental preservation was a wakeup call to many organizations, and in just seven years, the company had secured long-term agreements with 10 of America’s Top 100 private fleets.

Between 2016-2020, Fleet Advantage continued its mission to help fleets change the way they see the environment, as well as their impact. The vision of business intelligence solutions helped companies reach ESG goals while promoting sustainability through optimizing vehicle specification to be more fuel efficient and to align with the duty cycle as well as geographical locale. These solutions also specify lighter components that allow for longer maintenance intervals which reduces environmental hazmat waste disposal.

In 2022, the company introduced yet another first-of-its-kind program in the transportation industry to help corporate truck fleets certify their greenhouse gas emissions (GHG) output, recently mandated under a proposed rule issued by the Securities and Exchange Commission (SEC). Today, Fleet Advantage is the only finance lessor that has been certifying such measures for a decade with a focus on tractor trailer fleets that operate high annual mileages (MPY).

Today, companies are boasting vastly improved environmental records while implementing ESG strategies in front of customers, regulators, and other critical stakeholders. In total, Fleet Advantage has saved customers approximately $250 million and approximately 175,000 metric tons in emissions since inception.

Ultimately, Fleet Advantage's goal is to help the industry become as sustainable and green as possible. Every effort Fleet Advantage puts forth is to benefit all – the environment, truck drivers, motorists and the company’s customers, vendors and stakeholders. In the next five years, Fleet Advantage plans to further advance technology that helps the transportation industry continue to deliver goods across the nation efficiently, sustainably and safely.

Food Logistics: Canada moved the date for full enforcement of its electronic logging device mandate to Jan. 1, 2023. How will this mandate impact your company and the way it does business across the border? Please detail pros/cons.

Antonellis: Full enforcement of ELD devices will bring several challenges that fleets will need to be cognizant of. The toughest part is supporting the driver as they switch from U.S. regulations to Canadian regulations. This problem has been made significantly easier with over-the-air tractor updates that allow speed and dash parameters to be changed without having to engage the driver. The second advancement is the ability for all major ELD providers to recognize when a driver enters Canada and adjust the warning notifications such as hours of service or inspection requirements. Much of the knowledge on how to cross the border can be done by the driver manager. In my experience, having your systems prepared allows you to be flexible regardless of the driver or route.

Food Logistics: What kinds of technologies are in place to help autonomize trucking?

Antonellis: Human drivers have the advantage of being able to easily adapt to varying situations on the road. However, the computers that pilot trucks literally have to be instructed through written rules in lines of code leveraging data, sensors, applications and technology features that guide it safely down the road.

Human drivers have the luxury of understanding the intent of other drivers on the road, and estimate the closing speed of an overtaking vehicle and make a “best guess” about whether there’s enough space and time to make a move. However, the computer driver knows precisely how fast a car is traveling, and how many seconds — to a couple of decimal places — it will take the car to close the gap.

Software engineers today are leveraging artificial intelligence to attempt to infuse the truck’s computer with data-based intuition rather than pure logic so that it behaves more like a human — but without the human propensity for error.

In place of human eyes and brains, automated vehicles are being developed to use an array of sensors to gather information on their surroundings, including cameras, radar, lidar (light detection and ranging) and thermal imaging or infrared sensors.

These are all critically important because while we are not seeing widespread fully autonomous trucking, we are seeing portions of the drivers’ activities being monitored or managed with little or no driver involvement. These changes started with a focus on safety and fuel consumption. This is not a surprise as these two metrics are staples in every successful trucking operation.

Other areas to consider include technologies like collision avoidance, lane departure and crash mitigation, which will intervene if the driver is not responding as would be expected to limit the chance of a crash. In the most recent safety offering from Bendix, a tractor will apply the brakes to avoid a collision. I advise every fleet professional to test drive advanced technology to understand the impact it can have.

Fuel management has also been managed with pre-set parameters for the last decade. Starting with idle shut down and evolving into predictive cruise and pedal management. These tools help apply fuel and power the way the trucking company wants it to be and not at the designation of the driver.

Food Logistics: Let’s talk fuel prices. Currently, the national average is sitting at $5.12 a gallon for diesel fuel. How are the rising fuel costs impacting your company? And, what does this mean for the future of electrification?

Antonellis: Fuel is typically the largest cost of TCO for any fleet. When fuel rises quickly over a short period of time, it becomes extremely hard for a fleet to pass this cost along to their customers. During these times, making sure your maintenance is up to date is critically important. Key items that affect MPG performance are not limited to but include aftertreatment, fuel management and tires. Keeping these systems in good working order will ensure your tractor performs at peak performance.

The best way to ensure your fleet is running fuel efficient is to manage your life cycle. With the current supply chain challenges, ordering and receiving new tractors cannot be reactive to increased fuel costs. With newer tractors continuing to have increased MPG, the decision to reduce your average age becomes easier with diesel over $5 per gallon.

The average driving MPG for a 500-unit fleet operating a 5-year life cycle is 8.41. The average MPG for an 8-year life cycle is 7.90. If organizations switch from an 8-year life cycle to a 5-year life cycle, they will net a total fuel reduction in gallons of 2,494,770. This is not a difficult task and its impact over 5-10 years would be significant, producing a potent reduction in CO2 of 25,122 metric tons and 6.1%.

These strategies recently helped two top-100 fleet organizations eliminate over 55,000 metric tons of CO2 while conserving over 5 million gallons of fuel. At $5.12 per gallon of diesel, that equates to improved MPG and over $25 million in reduced fuel expenditures.

Having your life cycle planned out and equipment ordered for the next 2-3 years is the new normal.

Electric can play a role where the vocation of the tractor matches the current capability. The max range for class 8 electric is 200-250 miles and requires 8-plus hours of charging based on charger type and temperature. Electric could be an option if you have a need that fits into this range. The typical Class 8 electric tractor will cost about $360,000 and charger cost at about $40,000, with infrastructure cost varying by location and current power supply. We have recommended that many of our customers review the electrification of their yard trucks as the range in over-the-road class 8 improves. Electric has been leading the headlines, but I believe the final solution on the journey to ZEV vehicles ends with a multi-fuel approach, including electric, hydrogen combustion, natural gas and hydrogen fuel cell.

Food Logistics: The Trucking Action Plan. How will this and other program help curb the driver shortage? From where you sit, what else needs to be done?

Antonellis: Driver shortages are among the most challenging issues for the industry. Fleets will most likely continue to experience a shortage of professional drivers with the underlying causes showing no signs of stopping in the coming year. The American Trucking Association believes it needs 80,000 more drivers. This number may even swell to surpass 160,000 drivers by 2030. High demand, a lack of new drivers and retiring older drivers continue to play into the issue.

Driver shortage and the retention of drivers were listed as the Top 2 issues being faced by transportation firms according to the American Transportation Research Institute’s (ATRI) 2021 report. Including drivers in the conversation around safety initiatives and acknowledging their input is important for retention strategies. As more companies replace aging trucks with newer, safer equipment on the roads, they will keep drivers and others on the road safer, retain drivers at a higher rate and also enjoy substantial savings in reduced accident and litigation costs as well as lower maintenance and repair expenditures.

Another reason for the driver shortage has been the average age of drivers, which has been climbing for many years now. It is harder to attract younger drivers to the profession, which reinforces the need to build a fleet replenishment plan around shorter trade cycles whereby trucks are increasingly spec’d for newer, advanced safety features that keep drivers safe while returning them home to their families more frequently.

The DRIVE Safe Act, part of the $1.2 trillion infrastructure bill President Joe Biden recently signed into law, should help pave the way for drivers under 21 years old to enter interstate trucking. It requires transportation organizations to utilize industry-leading technology, including active braking collision mitigation systems, forward-facing event recording cameras, speed limiters set at 65 mph or less and automated manual transmissions. These requirements further illustrate the need to spec for newer trucks. What’s more, the recently launched Truck Action Plan, part of the Infrastructure Bill, is focused on ‘getting Americans working in better trucking jobs.’ Newer, reliable trucks with advanced safety features is a central place to start in improving the quality of these jobs.

Progressive-minded organizations continuously include their drivers in specification conversations and even poll drivers for input during the process, so they feel like their voice is heard. By creating this type of culture, fleets will be more successful in creating quality jobs and retaining younger drivers.

Food Logistics: What are some things not addressed above that may be pertinent to our readers regarding transportation trends and technologies in the cold food chain?

Antonellis: Entering 2022, food distribution companies continue to deal with a host of challenges carrying over from 2021, including driver shortages, logistical changes due to a fluctuating pandemic environment and asset management hurdles that continue to impact organizational bottom lines.

However, leading fleets are realizing that they can recruit and retain more drivers by building a culture that acknowledges safety and driver input while leveraging a more aggressive trade cycle driven by flexibility in operations and finance. This has been helping companies reduce overall costs while adhering to a long-term strategic asset management plan that helps organizations specify trucks with advanced safety features in mind.

[CLICK HERE to read the article in full].