Over the past few years, perishable food providers have undergone a sea of change regarding the ways in which they manage their transportation and logistics programs. Although temperature and location tracking capabilities have long been a critical part of their standard operating procedures (SOPs), many operators have utilized these tools mostly for the ability to respond to temperature excursions as they occur. But, continuing advancements in software technologies are enabling powerful data analytics and accelerating the transition from traditional reactive cold chain management to more proactive, insights-driven approaches.

Like most cold chain operators, providers of perishable food have become inundated with data from nearly every angle. From in-transit temperature tracking and monitoring devices to carrier and cold storage facility statuses, this abundance of data has been largely underutilized. Most operators simply do not have the internal resources to fully utilize this data, i.e., aggregate it into a unified view and process it to extract transformative insights. When it comes to data, many companies in our industry echo a similar refrain: “Yes, we have all this data. But, what exactly do we do with it?”

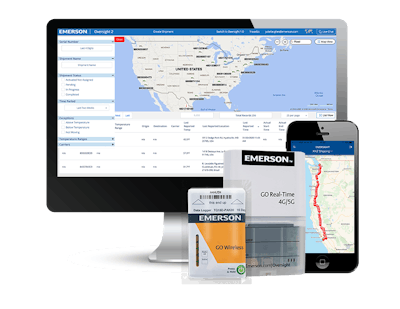

Today, all that is changing. Software is enabling the creation of transportation and logistics portals that not only integrate previously siloed data streams, but also leverage modern data analytics techniques to usher in a new era of operational insights. Instead of reviewing and reacting only to today’s data and making business decisions based on individual events, companies can look back on past months and years to identify patterns and trends.

This is fundamentally transforming the quality assurance (QA) processes of perishable food providers, shifting the paradigm from reactive management to making proactive decisions to correct problems before they happen.

But, even with these expanding insights, many companies also may not have the resources to evaluate them, make the appropriate course corrections and implement necessary changes to their SOPs. That’s why more producers are seeking software and service providers who can solve their data challenges and support various aspects of cold chain management. Let’s examine how a producer of perishable food might take the next steps toward a more proactive approach.

Integrated separate islands of data

The journey starts by aggregating various silos of information. Consult with a cold chain software provider who can help to consolidate your critical data streams into one unified software system. This step alone can deliver multiple benefits to your processes:

- Simplify data entry by not having to log in to multiple systems

- Assign shipment information to tracking devices to automate previously manual data entry

- Transition from a multiple-system model to utilizing a single-software platform

By moving traditionally separate islands of information into a singular platform, companies can lay a strong foundation for data-driven insights that inform critical business decisions.

Access insights via reports and scorecards

After the data is consolidated into one system, the software can begin to deliver expanded, higher-level and historic insights. For example, detailed reports and scorecards can pinpoint which carriers are demonstrating patterns of transporting goods at higher-than-expected or unacceptable temperature ranges. You can then correlate this data to see if there is also a pattern of loads being rejected when using specific carriers. With this information, you can proactively engage problematic carriers and inform them they will need to fix their temperature control issues before moving forward.

Other potential problem areas and questions that can be answered with these insights include:

- Which shipping lanes have repeated temperature excursions?

- Which cold storage coolers are not maintaining proper temperatures?

- Are there any distribution centers (DCs) that allow frequent temperature deviations?

- In which season or time of year are most excursions taking place?

Often, year-over-year seasonal analysis trends will reveal temperature spikes in produce during the summer months. Software allows operators to drill down to uncover root causes of these issues and make the necessary corrections or process improvements.

Engage professional and/or consultative services

Many companies simply may not have the internal resources to follow up and resolve the issues that these newfound insights can provide. If that’s the case for your organization, consider engaging the consultative services of a professional cold chain management provider. These experts offer companies a variety of services to help resolve the most pressing issues within their perishable supply chains.

For example, if the software uncovers the common trend of having higher produce temperatures during the summer months, companies can turn over the investigation of root causes to these professionals. Using software reporting capabilities, they can drill down into specific trips to help understand how and where temperatures are spiking. Possible areas of exploration include:

- Poor container insulation or refrigeration during the summer heat

- Improper produce pre-cooling procedures

- Flawed shipping processes

- Lack of temperature control at DCs

When you consider that companies may be evaluating tens of thousands of trips — and are more accustomed to handling individual issues, rather than larger trends — it’s easy to see how they may need help in exploring root causes. Not only can cold chain management professionals help to aggregate data and illuminate underlying issues, but they can also help to change producers’ overarching processes and business procedures.

And, since these insights reside within the software, much of this analysis can be performed remotely without requiring an on-site visit.

Partner with experts to augment cold chain management

By taking the steps detailed herein, companies can be well on their way to proactive cold chain management. Along this journey to greater insights, many discover weaknesses in their capabilities of which they may not have been previously aware. Professional cold chain management software and service providers can deliver a full range of services to fill in the gaps and shore up your capabilities.

From providing services that augment specific functions to offering 24x7 cold chain management, these experts can help you to redefine your SOPs based on a new understanding of your perishable supply chain. Software and services can deliver the transformative insights and expert support to transform your cold chain management from a state of reacting to daily emergencies to a more effective, efficient and proactive operation.

![Adobe Stock 280800711 [converted]](https://img.foodlogistics.com/files/base/acbm/fl/image/2021/08/AdobeStock_280800711__Converted_.611e898daa123.png?auto=format%2Ccompress&fit=crop&h=167&q=70&rect=0%2C53%2C900%2C507&w=250)