Let’s say you’re taking your regular commute home from work via train. On board, there are easily-accessible touchscreens on which you can order and pay for ingredients for tonight’s dinner or a microwaveable prepared meal. Not long after, you arrive at your local stop, drop in to the retail outlet close by, pick up your order and head home. Sound futuristic? It’s been happening in South Korea for five years.

Or consider the notable advent of ingredient-and-recipe meal kit services that have sprung up recently like shitake mushrooms—Blue Apron, Hello Fresh, Home Chef, to name just a few. In the United Kingdom, customers can now choose between ordering delivery at home, as their American cousins are obliged to do, or picking up a box of ready-to-cook ingredients at a convenient retail store.

In the UK, for more than 10 years now, established large supermarket chains have been offering customers much smaller outlets in densely populated areas with great success. Add to that a growing customer demand for fresh, often locally sourced food, and there’s been a revolution in refrigerated food distribution. All indicators point to a similar shift in consumer food-shopping patterns in the United States. Food suppliers will be faced with a demand for more frequent, less predictable deliveries, while continuing to drive costs down. What can distributors of chilled food products learn from their counterparts across the ocean?

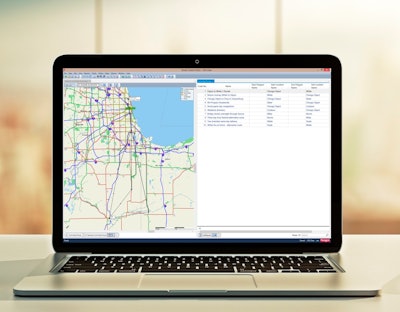

An important priority has been to shift from fixed truck delivery routes to a dynamic routing strategy. With dynamic routing tools, companies can use powerful mathematical algorithms to master the vast complexity of possible multi-stop route plans and flex quickly to adjust those plans when needed.

Furthermore, delivery time windows are shrinking. One reason is that smaller outlets inevitably mean smaller staff teams who are operating the cash register and/or stocking shelves, as well as handling deliveries. That means far smaller tolerances when it comes to delivery times, because no one wants to be left waiting for a truck that hasn’t arrived while there is a line of customers out front. Retail outlets increasingly need real-time information about ETAs, communicated proactively by the execution software, accurate to the minute.

Food retailers that adopt dynamic route planning and execution tools will stay ahead of this volatile complexity. Take the example of British grocery distributor A.F. Blakemore Logistics, which trimmed 600,000 miles off its delivery routes and was able to make a 10 percent reduction in its fleet after implementing a dynamic routing and scheduling solution.

Other food distributors have been able to make smart decisions about the locations of warehouses, the size of trucks they need, and even whether it would make sense to switch from palletized delivery to roll cages (which take up more space, but are easier and quicker to handle at point of delivery). They can do this all without spending a cent, using the modeling capabilities of sophisticated route optimization software in order to run myriad what-if scenarios.

Meanwhile, they can make sure every truck mile counts, maximizing the assets and processes already in place, while minimizing the effect of the pressing current driver shortage. Other benefits include being able to automatically feed driver hours of service restrictions, time-of-day constraints in densely populated areas, receiving dock hours and a host of other important elements into the software’s algorithm.

The plain fact is that most food distribution companies are already struggling to come up with a workable, flexible route plan for delivery trucks. Anticipating the coming changes in customer demand, retail outlet size and sourcing patterns mean dynamic, optimized routing will become an essential competitive factor.

Using all assets dynamically and efficiently involves ensuring that routing plans are executed and continually improved by constructive, ongoing interaction between the teams executing the plans and those planning them. That way, the delivery tail isn’t wagging the product dog, and you can concentrate on delivering excellent customer service and retaining a competitive advantage.