Temperature loggers and other monitoring devices have improved accountability throughout the cold chain by providing clear evidence of temperature abuse. This benefits stakeholders at every level by helping users ensure the quality of perishable foods and pharmaceuticals and providing objective data that enables proper quality control (QC). Data has also been useful in the claims process if a rejection happens. As technology has matured, experience has shown that carrier compliance often improves if they know a logging device is in the trailer.

These capabilities are improving, providing more granular data with the potential to reduce waste even further while simplifying QC processes. It’s now possible to add temperature measuring points to trailers and containers, and the cost is a small fraction of the load value.

Enhancing temperature data improves QC

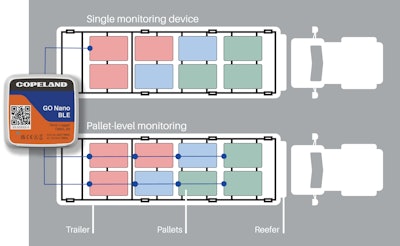

Logging devices can warn QC teams of temperature excursions at a glance. That’s great when the entire load is affected, such as when a driver turns off the reefer to save fuel. But what if temperatures vary throughout the trailer?

Here’s a real-world example: If a cooling system develops a leak, part of the trailer could be temperature-compliant, while another section is too warm and a third is too cold. With a single monitoring device, a hot or cold spot in the trailer could cause the entire load to be rejected, even though some product wasn’t affected. Depending on the location within the trailer, non-compliant temperatures could also be missed.

These risks can be minimized by monitoring temperatures throughout the entire trailer, using cost-effective devices placed on each pallet or in multiple zones. More granular temperature data gives customers the option of accepting a portion of the load, potentially providing benefits like:

- Less waste of food and medications

- Reduced costs for disputes and insurance claims, since rejected loads may be smaller

- Fewer expedited shipments (and the extra expenses associated with them) to replenish inventory in time

Enhanced monitoring is also beneficial when it doesn’t make sense to rely on a single temperature measurement, such as when less-than-truckload (LTL) shipments include comingled products with different safe temperature points. In addition, more detailed data can assist shippers and suppliers with FSMA 204 compliance by augmenting their key data elements (KDEs) via database APIs to share critical temperature information and corresponding timestamps.

Augmenting the dataset

A cost-effective method for monitoring temperature zones is to use Bluetooth low-energy (BLE) logging devices that can log temperatures for up to 60 days down to -22°F (-30°C). In this way, shipment data can be seamlessly synchronized with shipper and customer databases.

Preparing a load is quick and easy for shippers. Devices can be attached to each pallet or temperature zone once they’re staged for shipment. QR codes on each logger enable quick scanning with mobile devices to assign POs while indicating products and placement.

Gateway devices and mobile apps streamline receiving. Upon arrival, loggers communicate with Bluetooth gateway devices, which automatically upload temperature data to the cloud. QC teams can access data with tools, or have it passed through to their organization’s own systems via an API. Inspectors have the option to review temperature data by PO or individual pallets, and a thermal map summarizes the trailer’s condition throughout the duration of the shipment.

Even if no temperature issues are detected, granular temperature data can give advance warning of concerns within the trailer, identifying a need for inspection and potentially preventing future problems. Gateway devices can also be placed at key waypoints for greater end-to-end visibility.

Loggers can also be used on their own or in conjunction with real-time tracking devices that provide visibility into a truck’s temperature, location and/or security. High-volume customers can also scan device codes to increase automation in their QC processes, capturing shipment data in the cloud almost instantly.

Copeland

Copeland

Streamlining QC can strengthen the cold chain from end to end

Enhanced temperature monitoring offers a more robust way to improve quality throughout the cold chain. Every stakeholder — including shippers, retailers and consumers — benefits from lower costs and fewer hassles.

Bundling temperature data with POs and pallets enables suppliers and customers to see a complete picture of a shipment’s temperature history faster and more thoroughly. Ultimately, augmented temperature data represents a major step toward a safer cold chain with less waste.