FANUC America, the leading supplier of robotics, CNCs, ROBOMACHINEs and Industrial IoT solutions, will demonstrate its new CRX-10iA collaborative robot.

The new CRX-10iA and CRX-10iA/L (long arm version) collaborative robots set new standards in terms of ease of use, reliability and safety.

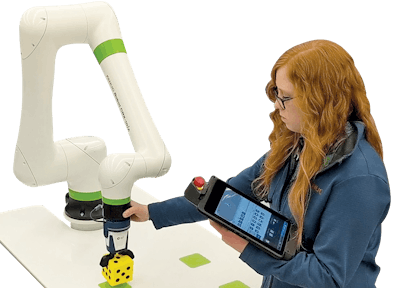

At the show, a CRX-10iA/L collaborative robot mounted on a lightweight, mobile structure will demonstrate how easy it is to move the robot around a work cell. Equipped with a Schunk Co-Act gripper, the CRX-10iA/L will pick and place small parts. In addition, it will perform its unique under flip motion that allows the arm to reach behind itself. Attendees will interact with the CRX-10iA/L in several ways to experience its sensitive contact stop, manual guided teaching and a new tablet pendant with a modern user interface.

FANUC offers the widest range of collaborative robots that can handle products from 4-35kg. The new 10kg payload CRX-10iA and CRX-10iA/L provide a reach of 1249mm and 1418mm respectively. Like the entire family of collaborative robots, the CRX-10iA and CRX-10iA/L are designed with FANUC’s world-renowned technology, proven reliability and sensitive contact detection that allows them to work safely alongside people in a variety of industrial and manufacturing jobs.

FANUC’s new CRX-10iA and CRX-10iA/L collaborative robots offer customers unique advantages, including:

Safety

· Safety rated contact stop detection like all FANUC collaborative robots.

Easy installation

· Customers – even those with no experience using a robot – can set up the new collaborative robots straight out of the box.

· Ergonomic design includes a lightweight and compact arm that fits in virtually any floor space configuration.

Extremely easy to program and use

· A compact R-30iB Plus Mini Controller.

· Manual Guide teach programming and a new tablet interface with icons for touch control – no programming knowledge required.

· The CRX-10iA/L arm’s under flip motion makes it easy to access/grab parts located behind the robot.

· Easily connects with third-party grippers.

· Supports FANUC’s intelligent features such as integrated iRVision® and iRPickTool software.

Ultimate reliability

· FANUC’s new collaborative robots offer the same world-renowned technology and proven reliability that customers expect from FANUC.

FANUC will also demonstrate robotic bin picking with the M-710iC/45M material handling robot and new 3DV/1600 vision sensor.

At the show, the M-710iC/45M robot equipped with the new 3DV/1600 vision sensor will quickly find and snap boxes of varying sizes and shapes in a large bin. The robot picks each package and drops it into another bin. Once the bin is empty, the sensor moves to the full bin and the cycle repeats. The demonstration highlights how the use of robotic vision is an ideal solution for applications in the warehousing, logistics and e-commerce markets.

FANUC 3DV/1600 Vision Sensor

The new 3DV/1600 vision sensor is lightweight and works as a fixed or robot-mounted 3D vision camera. The new sensor can quickly snap 3D images over a Z range of 2M, with a max field of view of 2700mm square, which is ideal for bin picking or line tracking large parts. The 3DV/1600 is part of FANUC’s iRVision suite of fully integrated and complete machine vision products for robot guidance and inspection. FANUC designs all of its vision hardware and software specifically for FANUC robots, providing customers with solutions that meet their production needs, and saves them the time and expense required by third-party vision suppliers.

Intelligent M-710iC Robots

The six-axis M-710iC/45M robot is a member of the family of M-710iC material handling robots with payload capabilities ranging from 12-70 kg. The robot provides high-speed operation, a 2606 mm reach and 45 kg payload. Its slim wrist, rigid arm and compact size allows it to work well in tight spaces, and a long reach and six-axis articulation makes it a good choice for palletizing, packing, bin picking, and other applications found in the warehousing, logistics and e-commerce.

M-710iC/45M Features and Benefits

· Compact size allows operation in small workspaces.

· Six axes, long reach, compact wrist and 45 kg payload make it easy to handle large loads.

· Best in class payload, wrist inertia, and reach for maximum system throughput.

· Flexible mounting (floor, invert, angle).

· High rigidity and the most advanced servo technology enable smooth motion at high speeds.

· IP67 rating (enclosed cover) allows operation in harsh factory environments with dust and oil mist.

· Supports iRVision, ROBOGUIDE/iRPickPRO Simulation, iRPickTool, ROBOGUIDE/PalletPRO Simulation, PalletTool, Force Sensing, Line Tracking, and Indexing options.