Food loss and waste are a serious concern—an estimated one-third of all food goes in the garbage. And while food loss is bad enough, in light of global food shortages, it also has an environmental impact. Rotting food in landfills produces methane, a known greenhouse gas, equivalent to 37 million cars on the road. Of all that wasted food, 40% is coming at all levels of the supply chain before the consumer is involved. The level of food waste and loss in the supply chain is largely due to a lack of full visibility and control over products as they are traveling throughout the supply chain.

Food producers and processors are increasingly implementing sustainability activities as part of their corporate responsibility goals. Many businesses have plans in place to reduce their food losses and carbon impact, often with specific targets in mind. Some are setting ambitious goals, aiming for sustainable water use, 50% waste reduction by 2030, and even becoming carbon neutral.

Real-time supply chain monitoring solutions that leverage reusable data loggers are enabling enterprises to minimize product loss and actively reduce their carbon footprint.

Food loss and waste caused by supply chain breakdowns

Most disruptions in the supply chain are regional and short-lived, such as ones caused by hurricanes, winter storms, or other types of natural disasters. The COVID-19 pandemic has dramatically increased supply chain breakdowns for numerous reasons. Entire countries and municipalities have shut down, and consumer buying habits have drastically shifted. Supply chains have been pushed to their breaking point, especially the food supply. It is essential—now more than ever—to get food to retail locations and keep it out of landfills. But, when routes get changed, drivers are not granted entrance to municipalities due to shutdowns, or ports are closed, many food products might not ever make it to market. Logistics failures throughout the supply chain can make for shortages at the retail level. Using end-to-end supply chain technology to minimize disruptions is one way to avert a looming disaster of empty grocery store shelves. Real-time technology allows food producers and third-party logistics providers to know exactly where the goods are and what routes are optimal.  Controlant

Controlant

Food loss and waste due to temperature excursion

As stated previously, 40% of food loss happens at the supply chain level before it ever hits the consumer. While some food loss comes from inadequately staffed production sites, it can also occur because the food was stored or transported incorrectly, rendering it unsafe for human consumption. Foods that spoil quickly like dairy, meats, fruits, and vegetables need to be maintained at constant temperatures to ensure freshness and increase shelf life. While real-time visibility cannot change the food harvesting or processing procedures, it can ensure that products are transported and stored at optimal temperatures.

However, many companies have been reluctant to implement digital solutions as a way to reduce food loss and waste due to temperature excursions. Research has shown that businesses that do so see improved margins with a more efficient supply chain, often off-setting the investment in the technology. This means that there is room for improvement for many organizations to implement real-time visibility solutions to keep more food in grocery stores and restaurants and out of the landfill.

Food loss and waste caused by rejected and replacement shipments

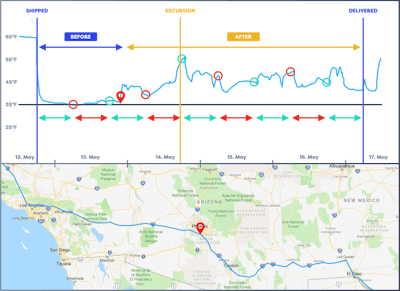

Another consideration is the operational and product waste created by inefficient processes due to a lack of total supply chain visibility. With passive data loggers, a temperature deviation may have occurred during transport. However, this remains undiscovered until the delivery is made, and often the food goes to waste while quality assurance teams investigate. Every wasted shipment means stock outages, and another replacement must be hauled across the country. There is an environmental cost associated with the manufacture, transport, and distribution of these replacement products, including water consumption, plastics produced (and discarded), CO2 emissions, and fuel. Not to mention the spoiled food ends up in a landfill. Controlant

Controlant

The benefits of real-time monitoring technology to reduce waste and loss

Many food producers and retailers have signed on to the EPA's Food Loss and Waste 2030 Champions program, committing to cutting food loss in half by 2030. Having a reusable real-time solution that offers actionable analytics to prevent loss and waste is an easy step to take. Real-time visibility enables all stakeholders to proactively reduce the carbon footprint of perishable waste, provides practical benefits of lowered costs on reduced food losses, and drives overall sustainability efforts.

Controlant

Controlant

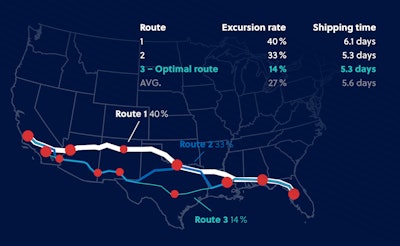

In addition to the real-time data that a monitoring program provides, longer-term trends and performance analytics regarding particular lanes, points of interest such as airports and harbors, packaging types, and so on, are easily discovered. Dashboards can now enable manufacturers and logistics providers to determine where the most substantial risks occur within their supply chain, and subsequently, mitigate them.

Reducing your environmental impact

Organizations in the food supply and distribution chain are demanding corporate responsibility from suppliers and logistics providers that address their environmental impact. With the information and analytics possible through wirelessly connected temperature monitoring solutions, enterprises can build a concrete plan of action for reducing waste throughout the supply chain and then work with all stakeholders to implement it.

Dashboard data allow supply chain teams to quickly reference the reduction in temperature excursions and shipment rejections resulting from their proactive monitoring and visibility program. Real-time data can reduce fuel costs by helping delivery drivers and logistics companies choose shorter routes with fewer excursion opportunities.

Continuous shipment monitoring prevents sustained temperature excursions, resulting in prolonged product shelf-life and fewer lost loads. Real-time data can assist grocery retailers and restaurants by helping them only order is needed from suppliers, thus reducing the possibility of unused products being thrown away. With all of this information, businesses are equipped to make decisions that get more food safely to retail locations, and ultimately the consumer. Controlant

Controlant

Moving forward

External pressure to embrace corporate responsibility programs aside, businesses should not overlook the benefits of adopting innovative solutions as part of their sustainability efforts. Enterprises looking to save money in the long-term by switching to more sustainable solutions and improving supply chain efficiency in the cold chain are now seeing substantial cost and resource savings. As a result, some companies now consider sustainability performance an essential part of the overall supplier performance equation, in addition to key requirements of quality, cost, and delivery.

The potential business benefits of greener supply chains are considerable. Companies that succeed in making their operations more environmentally friendly can expect operational cost savings due to less waste, reduced fuel, energy, transport costs, and a lack of compliance penalties. In 2017, more than 4,800 companies reported supply chain emission reductions amounting to 551 million metric tons of carbon dioxide. This equates to $14 billion in savings and does not factor in the additional cost savings arising out of reduced replacement products and less food waste. Moreover, supply chain improvements of this nature invariably enhance an organization’s brand and reputation considerably.

As an industry, we need to recognize the opportunity for key stakeholders to work together to stimulate innovation and technology adoption that can reduce waste, keep food out of landfills, and positively influence climate change. Although the requirements may take many years to generate a substantial impact, the journey must start today.

The potential for what can be achieved through technology and collaboration to improve the visibility, efficiency, and sustainability impact on the global food supply chain working may help shape the future.