The logistics industry saw its share of disruptions in 2024 ranging from the Baltimore bridge collapse and worker strikes to natural disasters, all of which impacted shipping routes and warehouse operations.

While devastating in nature, these challenges offered warehouse operators an opportunity to reassess and refine their strategies for greater resilience and efficiency.

Moving into the New Year, predictions for 2025 highlight the importance of human-centricity in tech solutions and the crucial role actionable data will play in unlocking and driving productivity gains.

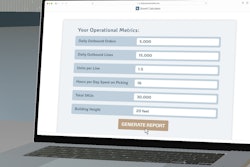

1. Organizations will feel the pressure to expose hidden inefficiencies with data insights.

Despite the availability of advanced wearables today, many warehouses continue to rely on legacy solutions such as handheld scanners, alongside manual paper-based workflows and fragmented processes. Compounding these challenges is evolving workforce trends, marked by turnover and an aging labor force, eroding hands-on knowledge and creating gaps in accessing critical supply chain information in real-time.

Balancing efficiency and precision are a delicate dance. Leaders will face mounting pressure to move beyond the status quo and address the limitations of legacy systems, whether it's relying on workforce knowledge, or standalone management systems. While the vision of a fully unified data ecosystem, one that bridges silos and offers an interconnected view of warehouse operations, may be aspirational, most organizations struggle to unlock real, actionable insights from their existing data streams.

This is where technology can play a crucial role enhancing the capabilities of warehouse management systems (WMS). Tools that illuminate specific areas of the supply chain and make data actionable can give warehouse leaders the agility and productivity they need without adding unnecessary complexity. By replacing traditional handheld scanners with innovative wearable solutions, companies enable workers to access and act on data, reducing friction at every level.

Whether it’s streamlining supply chains, or optimizing the workforce, this unifying approach, or the ability to pull insights from a single source of truth, will be the defining characteristic of successful warehouses in 2025 and beyond.

2. Using technology and AI to augment human performance.

The logistics sector stands at a crossroads: a pressing need for technological advancement, yet the hesitance to invest persists, fueled by concerns about artificial intelligence (AI’s) role in the workforce. Embrace technology that augments human performance, rather than replace it. For example, if technology can perform tasks like monitoring workflows, why not also use it to detect or prevent potential worker injuries?

The logistics industry cannot afford to wait, and while technology adoption is critical, it must prioritize simplicity and deliver immediate value, beginning with moving away from outdated practices like paper-based workflows. Adopting new technologies also shouldn’t come at the expense of the workforce; rushing into any technology adoption can overlook what staff actually need. Often, this can lead to confusion, frustration, and, ultimately, resistance to change.

3. Retail runways will continue to extend.

The ongoing trend of extended sales in the retail industry—where shopping events start earlier and last longer is here to stay. From holiday promotions kicking off well before traditional timelines to extended clearance periods, retailers have learned to adapt to changing consumer behaviors that prioritize convenience and year-round deals to drive purchasing behaviors and give revenue a short-term boost. This shift places new demands on supply chains to maintain agility and productivity throughout prolonged periods of sales activity.

4. Nearshoring will continue to gain momentum.

In 2024, major companies have increasingly embraced nearshoring as a strategy to reduce costs and enhance supply chain resilience. While not a new concept, trade regulations, coupled with the ongoing need for agility and efficiency, are driving renewed interest in the approach, particularly across North America. As businesses continue to prioritize resilience and efficiency, the nearshoring trend is expected to gain further momentum in 2025, positioning regional supply chains as a competitive edge.

5. Worker safety will come into the spotlight.

Worker safety will become a central focus in the logistics and supply chain sector, as businesses face scrutiny over practices and as employees increasingly advocate for safer, more supportive environments. Safety is not just a compliance issue, and with employees now more willing to make their voice heard—or even vote with their feet—employers cannot ignore the importance of addressing worker concerns about safety and well-being. But prioritizing worker well-being isn’t all about responding to employee demands; it's a strategic move on the part of supply chain operators to prolong the workforce, which will ultimately reduce turnover, injuries, or both, all of which come at a cost to the business.

Logistics is at a turning point, and disruptions are not going away. From global supply chain challenges to unexpected local events, the sector will continue to face upheavals that test the resilience of operations. Supporting workers and looking after their well-being allows them to perform their best work. The future belongs to human-centric solutions—intuitive tools that empower workers and actionable strategies that can deliver visible, meaningful impact.