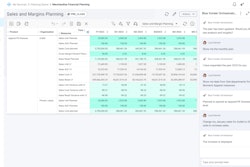

AutoScheduler.AI introduced Centralized Warehouse Orchestration, a solution that gives companies a centralized view of multi-site data.

Called AutoPilot Central, the solution enables supply chain executives to get an aggregated bird's eye view across multiple sites, rank them and take corrective action for areas out of service to mitigate risk across the network.

“With the pace at which warehouses introduce new technology and dynamically change, managing an operation has become overwhelming, especially since leading shippers with multiple sites often have different warehouse management systems (WMS) at each location,” says Keith Moore, CEO of AutoScheduler.AI. “AutoPilot Central provides a birds-eye view of multi-site data for centralized command and control of an entire distributed warehouse network. At the network level, the history and result of these plans can then be bubbled up to Directors and VPs of distribution to identify the potential flow issues that are going to occur inside of a network, which customers/shipments are at risk, and where action can be taken to avoid service failures.”

Key takeaways:

- AutoPilot Central aggregates multi-site AutoScheduler data using predictive analytics to enable top supply chain officers to rank the sites, quickly see which areas across the network are out-of-tolerance or at risk and take corrective action to mitigate risk before chaos happens.

- With AutoPilot and AutoPilot Central, leaders can reduce planning time by 97%; increase productivity per headcount by 16%; reduce inventory waste by 13%; reduce intra-campus transportation costs by 31%; double cross-docking utilization; optimize labor planning; and aggregate multi-site data for centralized warehouse optimization and risk mitigation.