Online shopping has increased 70% since the pandemic began, according to McKinsey. The additional demand has accelerated transformation in supply chains, putting strains on retailers' capacity and generating innovative solutions for companies to sell their products online. Particularly in the food sector, companies are developing new business models, new supply chains and new platforms to meet the demand for online orders.

Frequently food manufacturers, distributors and logistics operators reported that adding new users to the system was getting prohibitively expensive. The inability to manage and customize B2B user access permissions along with few promotion management capabilities was problematic. The B2B portal was not flexible enough for B2B workflows and user experience goals. Instead of stretching one system across B2C and B2B, decision-makers look for a B2B system on a cloud-hosted platform that will not drain resources during implementation, maintenance and operations.

Food manufacturers impacted by B2B e-commerce

Food manufacturers must be more available to new business opportunities. B2B e-commerce engages new customers as well as streamlining existing B2B relationships.

Upselling to existing customers becomes easier with an online portal that can feed customized content to specific customer groups.

The food industry engages in B2B e-commerce through internet market discovery exchanges used by food suppliers at any point in the supply chain. With very narrow margins in food manufacturing, B2B relationships reduce costs, increase efficiencies in procurement, storage and delivery to retail stores and distribution centers.

The use of B2B e-commerce allows retailers to share information about consumers' purchases and preferences. Food manufacturers are able to track products, sources, and movement from production to consumer.

The development of B2B e-commerce in the food industry fosters and demands vertical coordination. It favors consolidation of firms and changes the business culture from one of adversarial relationships to cooperation and trust. It changes the historical supply chain into a supply/demand loop while it lowers the cost of food.

With the dramatic increase in B2B e-commerce selling, the food logistics industry can ill-afford slow adoption of technology solutions that efficiently create dynamic workflows, product movement and lot traceability.

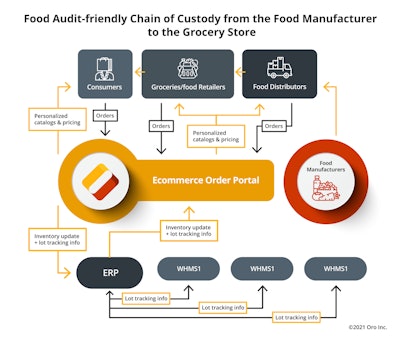

One food recall can shut down a manufacturer. Poor B2B supplier compliance can destroy order fulfillment and delivery. Mapping chain of custody (whether raw ingredients or finished goods) can be documented regardless of the database, customer relationship management, enterprise resource planning or other solutions currently utilized.

Food manufacturing linked to distribution

Once packaged food leaves the plant floor, the chain of custody must be tracked and monitored both for safety concerns and order delivery expectations. Orders placed in the morning are expected that afternoon. B2B e-commerce technology excels in keeping the chain monitored and efficient. This is particularly important as food manufacturers and distributors are deploying third-party logistics (3PL) providers and ancillary distribution center facilities.

B2B e-commerce monitors supplier risk and performance

Vendor or supplier performance is a key indicator that may fall outside the typical B2B e-commerce model. It is best when integrated because food companies must automatically track late deliveries, short shipments, pricing discrepancies and even quality audit results on every receipt. Every food company needs continuous records of the effectiveness—or ineffectiveness—of its vendors.