The warehousing industry is grappling with significant labor shortages, with 73% of warehouse operators struggling to source sufficient staff to meet business demands. This scarcity is exacerbated by high turnover rates, with major players experiencing turnover exceeding 150%. Adding to the challenge is the surge in e-commerce orders, peak season surges, and consumer behavior shifts, creating an ecosystem of demand fluctuations that make planning for and managing labor extremely inefficient. A perfect storm of high demand, rising costs, and new tariffs challenge warehouse operations to adapt quickly to maintain operational efficiency.

Why labor management is business critical

Labor management in the warehouse industry is business-critical because it directly impacts operational efficiency, cost control, and service levels. Effective labor management helps warehouses optimize workforce allocation, forecast labor needs, and improve operational efficiency, ensuring profitability and long-term success. Fluctuating demand, high turnover, and labor shortages are challenges that can be addressed with labor management tools. As labor accounts for over 50% of total warehouse operating costs, efficient labor management ensures optimal workforce utilization, reducing overtime expenses and unnecessary labor spending. Innovative solutions like warehouse orchestration systems are emerging in response to these challenges.

What are warehouse orchestration systems?

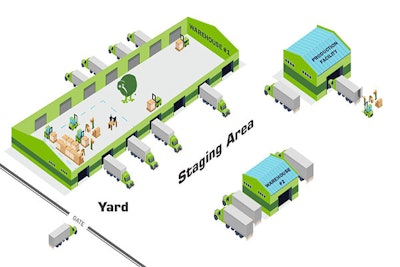

Warehouse orchestration systems intelligently allocate tasks to workers based on real-time data and predefined rules, ensuring assignments align with employee skills, availability, and workload. If bottlenecks or delays occur, the system automatically adjusts task assignments to maintain operational flow. This agility is essential, particularly during peak demand periods.

These solutions integrate data from warehouse management systems (WMS), labor management systems (LMS), and other essential platforms to provide real-time visibility into operations. This integration enables dynamic labor adjustments, allowing warehouses to adapt to fluctuations in demand efficiently. By optimizing task allocation and forecasting workload spikes, warehouse orchestration platforms help warehouses maximize productivity, reduce inefficiencies, and mitigate the impact of labor shortages.

Data-driven decision-making

Managers can leverage insights from warehouse orchestration systems to make informed labor management decisions. These systems help identify labor demand patterns, optimize scheduling, and predict future staffing needs, preventing labor shortages and reducing overstaffing costs.

By incorporating AI-enhanced algorithms and predictive analytics, warehouse orchestration systems forecast incoming orders and fulfillment timelines. These algorithms optimize labor allocation, inventory availability, and demand forecasting to ensure the right personnel are in place to meet operational needs efficiently.

Enhancing workforce utilization and centralized management

Effective workforce utilization is key to improving warehouse productivity. Warehouse orchestration systems balance workloads, preventing both employee burnout and underutilization. A centralized system allows businesses to manage labor across multiple sites efficiently.

A warehouse orchestration platform provides a comprehensive view of multi-site operations through centralized command and control. By aggregating data, these platforms use predictive analytics to highlight at-risk areas and redistribute excess labor from overstaffed locations to sites requiring additional support.

Without these insights, warehouse managers may struggle with daily order visibility, leading to costly labor imbalances. A centralized warehouse orchestration platform continuously monitors labor distribution, compares site performance under varying workforce levels, and forecasts labor demand based on historical data and predictive analytics. This strategic approach ensures optimal labor usage and reduces overstaffing costs.

For example, managing labor to meet demand—especially during early-day peaks—can be challenging in a warehouse operating three shifts with fluctuating truck arrivals. Warehouse orchestration systems help match available labor with real-time demand, ensuring smooth supply chain operations.

The transition from reactive to proactive labor management

Traditional warehouse labor management focuses on reactive measures—responding to staffing shortages, equipment breakdowns, or shipping delays as they occur. While necessary in fast-paced environments, this approach leads to inefficiencies and unplanned costs.

AI-powered warehouse orchestration solutions shift the focus from reactive management to proactive forecasting. By analyzing extensive operational data, these solutions detect patterns and predict bottlenecks before they occur. This capability enables businesses to anticipate labor shortages, potential delays, or equipment failures, allowing them to take preventative measures ahead of time.

The power of predictive analytics in labor management

Predictive analytics employs historical data, machine learning algorithms, and statistical models to forecast future labor demands and operational needs. Applying these techniques to warehouse management allows companies to anticipate potential issues before they impact productivity.

For instance, predictive analytics can forecast labor shortages by examining past workforce trends, seasonal fluctuations, and upcoming order volumes. The system can recommend staffing adjustments or resource reallocation if a shortage is predicted. Similarly, predictive analytics can predict equipment maintenance needs and potential inventory shortfalls, enabling proactive decision-making and minimizing disruptions.

Preventing bottlenecks and improving efficiency

Bottlenecks related to labor, equipment, or inventory significantly threaten warehouse efficiency. Delays increase operational costs and affect customer service.

Warehouse orchestration platforms provide real-time visibility into warehouse performance and identify potential problem areas. For example, if analytics indicate a specific shipping lane is experiencing delays due to increased demand, the system can suggest alternative routes to minimize disruptions. If labor shortages are forecasted, schedules can be adjusted, workers reassigned, or automation solutions can be deployed to compensate.

This proactive approach prevents bottlenecks before they escalate, optimizing resource allocation and workflow prioritization. By continuously monitoring labor demands and operational efficiency, businesses can maintain high performance levels even during peak demand periods.

Benefits of proactive warehouse orchestration

Transitioning to a proactive warehouse orchestration system offers several key benefits:

- Optimized resource allocation. Predictive insights enable efficient workforce, equipment, and space utilization. Businesses can proactively adjust staffing levels and deploy resources before disruptions occur.

- Enhanced labor efficiency. By forecasting labor needs, orchestration systems ensure optimal workforce deployment, reducing downtime and improving employee satisfaction.

- Minimized downtime and delays. Preventative scheduling of maintenance and workflow adjustments reduce the risk of operational interruptions.

- Data-driven decision-making. AI-powered insights help managers make informed decisions that enhance overall supply chain performance.

- Scalable and future-proof operations. Predicting labor demands and operational challenges allows businesses to build resilience against future disruptions, ensuring long-term sustainability.

The future of warehouse labor management

Predicting and preventing operational challenges is vital in today's competitive supply chain landscape. Warehouse orchestration solutions empower businesses to move beyond reactive labor management by leveraging AI-driven predictive analytics. Planning for the next shift is no longer sufficient—companies must anticipate and address tomorrow’s challenges today. By adopting warehouse orchestration technology, businesses can enhance efficiency, reduce costs, and maintain seamless operations, positioning themselves for sustained success in an evolving marketplace.