In the United States, food waste is estimated at 30 to 40 percent of the total food supply, according to the U.S. Department of Agriculture’s (USDA’s) Economic Research Service. The USDA has responded to this by calling for a 50 percent reduction in food waste by 2030.

The Food and Drug Administration (FDA) sees food safety as a prime issue. So much so that Jan. 4, 2011, then-President Barack Obama signed into law the Food Safety Modernization Action (FSMA), a ruling designed to shift focus from responding to food contamination to preventing it. And, 2017 is being hailed by some as the year of FSMA compliance, as many mandates set by this law must be met this year.

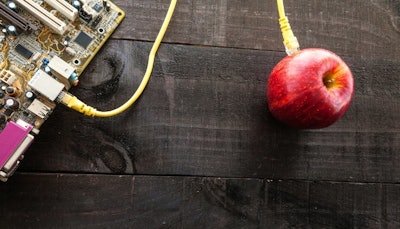

As those in the food industry race to meet these regulations and goals, it also might be the year of the Internet of Things (IoT) for an industry that has traditionally lagged behind other trades in its adoption of this technology.

Consumers already employ the IoT in their homes to turn on the lights, adjust the temperature and in using high-tech appliances that alert them when they need milk or when the wash is dry. But the IoT has the power to transform more than just how people live, it also can enable the food and beverage industry to monitor shipments in real time to ensure products are always stored at the right temperature, and are fresh and safe for consumers to eat.

“The IoT provides a completely transformational set of capabilities and business models for companies who embrace it, think creatively and understand the power of what connectivity and the resulting data can do for them,” says Neil Hampshire, chief information officer of ModusLink, a provider of supply chain management services.

The IOT's Fast Fixes for Food

Load Delivered, a freight broker and logistics services provider, identifies the top ways the IoT might revolutionize the food industry in an article titled, “Five Ways the IoT Impacts the Supply Chain.” They include:

1) Farms. By using IoT sensors and drones, farmers can capture data on crop growth, livestock health, monitor weather patterns, control water and energy use, and use predictive analytics to better understand their operations.

Will Yapp, vice president of business development for Senet, an IoT network provider, sees huge opportunity with irrigation. He explains soil monitoring for irrigation purposes is very costly. “In the past, the only way to monitor the soil was to stick a $1,000 probe in the ground. Because of the expense, a farmer could only do this every five to 10 acres,” he says. “But with a $20 IoT sensor, a farmer can now put in hundreds of devices to better monitor the soil and manage his yield. There is tremendous ROI in that.”

2) Warehouses and Production Facilities. In food warehouses and production facilities, the IoT can help tighten quality control, replenish inventory, monitor production and worker productivity, and better maintain production equipment.

Dr. Achim Kruger, vice president of Operational Excellence Solutions at SAP, stresses that with the IoT, there is “a lot more information available from products or assets that can help [food and beverage manufacturers] make optimal decisions. The IoT is really about combining data from the business and the shop floor to make better business decisions.”

The IoT also can help companies keep tabs on when their products leave the warehouse and their estimated time of arrival (ETA) for customers, states Sean Riley, director of strategic business solutions for Software AG, an ERP solutions provider. When a third-party is transporting products, and customers start calling to learn where their shipment is, using the IoT puts that information at the warehouse operator’s fingertips.

3) Food Safety and Recalls. The IoT can enable shippers to monitor food containers and trucks, and trigger alerts that head off spoilage or replace bad products before they reach customers. It also makes it easier to pinpoint contamination and spoilage to launch recalls. There are even emerging applications that enable shippers to better meet FSMA requirements.

“The IoT’s uses in the cold chain are a no-brainer,” says Sanjay Sharma, CEO of Roambee Corporation, an IoT supply chain and enterprise asset visibility company. “Companies are looking at how they can monitor the condition of their products within the supply chain in a way that can minimize the risk of spoilage and loss.”

4) Logistics. Here, companies can shift their approach from reactive to proactive. According to Load Delivered, “advanced Radio Frequency Identification (RFID) tracking offers unparalleled visibility into the food supply chain, monitors and controls temperature, and automates shipping and delivery processes.” In addition, shippers can track product location with GPS, optimize routes and gauge fleet performance.

Sharma sees shipment security as a key area for the IoT in regions of the country where shipments are routinely lost. High-value food and beverage shipments, such as alcohol, are particularly at risk. “In California, a lot of dried fruits are getting stolen in transit or at checkpoints,” he says. Putting IoT on these shipments lets shippers know where they are at all times while in transit.

By leveraging telematics data in real time, food and beverage companies can continuously calculate ETA, and should there be a deviation, they can take action. They can reschedule a shipment’s arrival time, or even schedule a second shipment via air to get products there on time, when time is of essence. “Your options for taking action are somewhat limited when you’re receiving data after the fact,” Riley says.

5) Consumer Applications. Finally, consumers can have a better handle on the products they buy. They will know how fresh the food is that they are buying and how long it will last.

With all of the potential applications, one would think that the use of the IoT would be more widespread across the food industry than it is. But despite its utility, Riley says adoption is actually very low. He explains that “food manufacturing, transportation and food sales are not the highest margin businesses in the world, so investments in new technology have to be very vetted out with an iron-clad ROI.”

Sharma agrees. “This visibility requires an investment in infrastructure, regardless of whether it is in hardware, software or people, and infrastructure is not cheap.”

However, Riley adds that food industry players can expect a clear-cut ROI in reduced overages, shortages and damages. “There will be a reduction in damages when products reach their destination, and are unusable, because they were maintained at the incorrect temperature,” he says.

It is for this reason that Sharma predicts in seven to 10 years “all shipments, no matter how small or how valuable they are, are going to be real-time monitored.”

IOT Tech Trends

Greater use of IoT data in the food industry is going to take time, education and technology, states Joe Scioscia, vice president of sales, for VAI, an ERP solutions provider. “We are very much at the tip of the iceberg,” he says. “But I predict we are going to see more use of the IoT in the years to come.”

Riley states that at minimum food and beverage companies need the following in terms of technology. “No. 1, they need the ability to ingest data fairly easily; which means they must have robust connectivity to their partners [in the supply chain,]” he says. “The second tool they need is continuous streaming analytics, which enables collecting data in real time and analyzing it to understand what it means. Finally, they need a tool to aggregate the data, which allows them to run short-term predictions fluidly, and respond to them.”

One technology poised to take the IoT world by storm; especially in the food and beverage industry, is Roambee’s Bee, which is a portable wireless locator packed with a variety of sensors. This GSM tracker is essentially a mini circuit board that houses a variety of sensors designed to monitor shock and vibration, temperature, humidity, tampering and more. The device also has a global SIM within it that enables customers to monitor their shipments locally as well as globally. The device then collects this data in real time and connects it to various back-end devices, such as an ERP solution from SAP. And, the system enables the company to set rules based on the data coming in in order to take actionable intelligence.

This technology takes 5,000 to 10,000 alerts about a shipment, and then, using rules defined in advance, trims that number to only those that require action. “Anybody can collect data, but how do you take 5,000 alerts and bottle them up into five alerts that are problematic?” asks Sharma. “This is something that requires a lot of data mining, artificial intelligence and machine learning. Just because a load’s temperature goes up 1 degree doesn’t mean they need to take action, but if it keeps going up, they may need to make a few decisions.”

IoT data from the Bee can help companies forecast better. If a company is shipping avocadoes from South Africa to the United States, it’s important to monitor the CO2 being released by the produce to manage the ripening process. Sharma states that while there are many sensors that provide this information, there needs to be a dashboard that explains what the readings mean. “Will the avocadoes be ripe by the time they reach their destination? Will they be under ripe? And what kind of changes do you need to make in transit so that the ripening process is accurate by the time it reaches the grocery store?” he asks.

Another IoT technology helping in the cold chain is Flexstr8’s Smart Label, which provides users with a complete temperature history of perishable goods. This disposable device is small enough to be integrated into packaging, and is an advantage over current temperature loggers, which are “expensive, bulky and have poor battery life,” reports Eric Casavant, head of product development for Flexstr8.

This logger has a life span of one year, and comes with a 28-kilobyte memory that enables it to collect 14,000 measurements. It has a temperature sensor embedded inside, and uses Near Field Communication, available on most mobile devices, to allow users to download temperature information.

“Accurate temperature logging and time stamping allows detailed analysis across the increasingly complex cold chain supply,” reports Ralph Roessler, president of Flexstr8 Inc. He reports that this enables companies to make corrections in real time and assign liability.

“This device introduces transparency,” adds Howard Pakosha, who represents Flexstr8. “When a product arrives at its destination, workers can use their smartphones to scan and see that three days ago, there was a temperature spike with this product, and the ripening process artificially accelerated because the truck driver left the reefer door open.”

FreshSurety also has an IoT product set to change produce transport. Its Assured Freshness system has been trialed with leading producers and grocery retailers and employs the IoT to measure and report fresh produce’s quality and shelf-life throughout the supply chain. This enables retailers to manage sourcing, inventory and merchandising based upon the actual shelf-life of each pallet.

Tom Schultz, FreshSurety CEO, says: “For the first time in history producers and retailers will know shelf-life and value of every pallet anywhere in the supply chain. This information will reduce waste and improve quality.”

The utility of this product can be readily seen with strawberries, which are only good for 16 days after picking, and with pitted fruits. The FreshSurety device has a sensor and analytics rules engine embedded within it that helps detect if a load of strawberries is good or bad.

“If a load of strawberries, for instance, is bad, you might only get 20 cents on the $1 for those strawberries. That is a huge economic loss,” says Marc Rippen, chief sales officer of FreshSurety.

The system prevents such losses by using low-cost chemical sensors to measure metabolites emitted by fresh produce as it ages. This information is transmitted to the cloud where it is converted by product-specific food spoilage algorithms into a quantitative freshness score for individual cartons and pallets.

The system includes a light bar on each produce pallet that signals real-time product quality and remaining shelf life. The device collects data every 10 minutes throughout the life of each pallet and collects information on temperature, humidity and pallet geolocation.

“We can see information about the product from picking to the flat level. We can see the worker who picked it, and if the fruit was picked carefully or handled it roughly. We can see the cold chain data, and see how the temperature was maintained,” says Rippen.

He adds that “this IoT solution combines food science and electronics. The system measures at multiple points to determine the trajectory of the food, and helps companies make decisions on which food must be sold first. It’s no longer a ‘first in, first out policy,’ but a decision based on scientific data.”

The IoT provides real-time visibility into the food chain. “That visibility can be translated into actionable business information,” says Sharma. “The IoT makes things work smarter, and makes them more transparent and more collaborative.”

The benefit, he adds, is greater food safety and security, and reduced food waste.