It’s March 25. In the midst of the Coronavirus disease (COVID-19). Schools and libraries are closed. Restaurants only offer drive-through or pickup service. Shoppers flood grocery stores, hoarding everything from toilet paper to frozen pizzas. In fact, the frozen food aisles emanate a scene from The Walking Dead.

Every day, the news breaks with updated cases, reports and status of how the United States—and the world—are safeguarding food, employees and the future of companies.

And, safeguarding food at a time when the nation hunkers down is an unprecedented situation.

For starters, the U.S. Food and Drug Administration (FDA) issued a temporary policy for FDA Food Safety Modernization Act (FSMA) supplier verification on-site audit requirements during the COVID-19 public health emergency “to not enforce requirements in three foods regulations to conduct on-site audits of food suppliers if other supplier verification methods are used instead.”

Plus, the travel restrictions and advisories associated with COVID-19 may make some audits temporarily impractical to conduct. The broad geographic footprint of high-pressure processing (HPP) capacity and additional cold supply chain services can help food and beverages brands ensure food safety, efficient distribution and extended shelf life from the processor to the end user.Universal Pure

The broad geographic footprint of high-pressure processing (HPP) capacity and additional cold supply chain services can help food and beverages brands ensure food safety, efficient distribution and extended shelf life from the processor to the end user.Universal Pure

“While our grocery stores are facing unprecedented demand, we are working with the industry to minimize disruptions in the supply chain due to COVID-19-related travel restrictions,” says FDA commissioner Stephen Hahn. “The policy will help to minimize disruptions, so that the food industry can meet the demand while also continuing to conduct supplier verification activities that are designed to ensure food safety and follow government travel restrictions and advisories.”

The FDA anticipates that receiving facilities and importers will resume on-site audits within a reasonable period of time after it becomes practicable to do so and update their food safety plans accordingly.

But, some protections already live in the FSMA requirements, according to Frank Yiannas, FDA’s deputy commissioner for food policy and response.

“A critical part of the U.S. Food and Drug Administration’s mission is safeguarding the human and animal food supply, helping to ensure that our food is not contaminated at any point during its journey along the supply chain,” he adds. “We do not anticipate that food products would need to be recalled or withdrawn from the market for reasons related to the outbreak, even if a person who works in a human or animal food facility is confirmed to be positive for the COVID-19 virus.”

What’s more is, evidence from the European Food Safety Authority (EFSA) reveals there is currently no evidence that food is a likely source or route of transmission of the coronavirus disease (COVID-19).

“Experiences from previous outbreaks of related coronaviruses, such as severe acute respiratory syndrome coronavirus (SARS-CoV) and Middle East respiratory syndrome coronavirus (MERS-CoV), show that transmission through food consumption did not occur. At the moment, there is no evidence to suggest that coronavirus is any different in this respect,” says Marta Hugas, EFSA’s chief scientist.

That being said though, the food and beverage industry still faces a host of food safety challenges, ranging from lack of traceability and transparency, to compliance and recall prevention.

“When it comes to food traceability, some are stuck in a past in which each segment in the food system is responsible for keeping track of food, taking one step forward to identify where the food has gone and one step back to identify the source. And, it’s largely done on paper,” says Amanda Turney, press officer, Office of Media Affairs, Office of External Affairs, U.S. Food and Drug Administration, Washington, D.C.. “However, with the emergence of new digital technologies and the continued advancement of sensor technology, many believe the one-step forward and one-step back model of food traceability is an outdated paradigm for the 21st century. When we look at how other industries are able to track through digital means, the movement of planes, ride sharing and packaged goods, it appears that we could be on the verge of real-time tracking when it comes to food.”

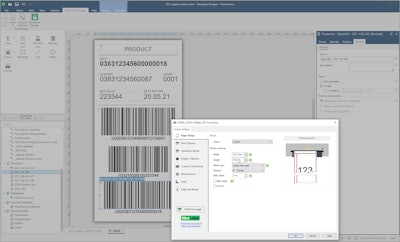

What’s more is, changes in food production and supply chains are becoming more complex, providing more opportunities for tampering and difficulties in track and trace. Label management systems allow manufacturers to implement a standardized method for producing labels and marking packaging across all processing locations.NiceLabel

Label management systems allow manufacturers to implement a standardized method for producing labels and marking packaging across all processing locations.NiceLabel

Food safety leaders are under tremendous pressure to gain customer trust by delivering high-quality food across the complex supply chain, as outlined in an expert column from Gisli Herjolfsson, co-founder and CEO of Controlant, San Francisco.

"Significant growth in the recent number of food safety incidents and recalls, an increase in media scrutiny and evolving regulatory requirements have placed increasing responsibilities on food safety leaders to regain consumer trust by delivering consistently high-quality food cross the complex cold chain, while meeting the various regulatory requirements," says Herjolfssen. "Every business is unique and maintains its own distinct operational requirements. What is common, however, is that the strength of a food brand is comprised of the sum of the operational, regulatory and reputational risk points that have been effectively mitigated by employing the right people, processes and technology."

When it comes to food traceability, some are stuck in a past in which each segment in the food system is responsible for keeping track of food, taking one step forward to identify where the food has gone and one step back to identify the source, says Amanda Turney, press officer Office of Media Affairs, Office of External Affairs, U.S. Food and Drug Administration, Washington, D.C.

"And, it’s largely done on paper," she adds. "However, with the emergence of new digital technologies and the continued advancement of sensor technology, many believe the one-step forward and one-step back model of food traceability is an outdated paradigm for the 21st century. When we look at how other industries are able to track through digital means, the movement of planes, ride sharing and packaged goods, it appears that we could be on the verge of real-time tracking when it comes to food."

Changes in food production and supply chains are also becoming more complex, providing more opportunities for tampering and difficulties in track and trace.

“To improve food safety in supply chain management is a combination of the people, processes and technologies involved,” says David Cahn, director global marketing Elemica, Wayne, Pa. “Supplier relations programs and performance tracking is a key initiative for many organizations to begin with to help mitigate potential risk. Initiatives to track ingredients by a lot or supplier needs to be able to go beyond a single tier of visibility to a multi-tiered network for complete visibility. Today, resource and implementations of digital supply networks is only growing at this point to accommodate the food safety or quality risks beyond the first tiers in the supply chain.”

Ensuring regulatory compliance

Ensuring regulatory compliance along the supply chain, particularly for refrigerated foods such as meat, seafood, processed agricultural products and ready-to-eat food is a great concern.

“We need to improve not only recall prevention, but also the effectiveness of actually recalling product. We can start with improved and more consistent training, while also evaluating the effectiveness of that training. Further, there should be a greater focus on keeping recall procedures current to regulatory requirements before a crisis occurs,” says Len Steed, food safety professional, AIB International, Manhattan, Kan. “Most companies are too reliant on third-party audit scores to confirm that their food safety systems are compliant when in fact their risk-based internal audit program should be their first line of defense for mitigating organizational risk. The challenge here is having highly effective internal auditors to find significant issues before they become a crisis.”

It’s the crisis management that sets apart the companies who’ve exercised food safety preparedness from those who don’t deem these issues as that important.

“Crisis management exercises for the types of food safety issues that could occur in your facility is an excellent way to calibrate your organization’s attitude and preparedness for a real event,” says Steed. “Preparedness will prompt a reality check as to why food safety is so important, and also establish ‘no debate’ attitudes for food safety.”

For its part, Park City Group/ReposiTrak, Murray, Utah, sees compliance as the most critical food safety challenge.

“There has been a dramatic expansion of suppliers during the last few years trying to gain traction in the hottest food categories like local, organic, gluten-free, non-GMO and CBD/hemp,” says Randy Fields, chief executive officer of Park City Group/ReposiTrak.

Another challenge is management’s commitment to ensuring food safety.

“The key to a successful food safety technology deployment will always be the people that implement the system, train the users and provide support during the operations,” adds Fields.

Likewise, crisis management exercises for the types of food safety issues that could occur in a particular facility is an excellent way to calibrate an organization’s attitude and preparedness for a real event. A Digimarc study reveals 80% of manufacturers will report a problem from mislabeled products on their primary production line, while 67% still use manual inspection methods.Digimarc Corp.

A Digimarc study reveals 80% of manufacturers will report a problem from mislabeled products on their primary production line, while 67% still use manual inspection methods.Digimarc Corp.

“Organizations take direction from their top executives. If the executive leadership team demands faithful execution of food safety requirements, then that will be the priority for the organization, and they will have a culture that is committed to food safety,” says Steed.

In addition to a lack of traceability lies a lack of a holistic view and understanding of potential risks can lead to food safety and quality failures, including public health issues, lost loads and unhappy customers.

“A lot of companies are still not aware of what innovative and disruptive solutions are out there for more accurate monitoring to help mitigate those issues,” says Mike Sharpe, president and CEO of Cooltrax, Roswell, Ga. “[For example], pallet and product-level monitoring, especially when paired with the reefer data, can help identify and manage food safety supply chain risk in real-time.”

Overcoming food fraud

When it comes to a safe supply chain, overcoming food fraud remains top of mind for most of today’s cold food and beverage processors.

That’s because they need to understand that adulteration of food products can be committed in many ways, including mislabeling, product substitutions or product adulterations throughout their supply chain, says Cahn.

“Technology does help the food processor assist in creating a sustainable and safe food supply chain,” he adds. “There are many solutions that help in conducting specific tests unique to their products, such as tests for added water in milk and specific pesticide/chemical residues on fruit/vegetables represented as organic. Others include infrared spectroscopy for specific beverages and supplements. But, from a supply chain perspective, increasing traceability is key. It is obvious that the more visibility into the supply that is provided will result in less risk. Technology around IoT and RFID used for labeling and packaging can enable product quality while also facilitating tracking and tracing throughout the supply chain, both upstream and downstream.”

Food processors also need to know that monitoring compartment temperatures alone is not enough, and that foodservice operators are requesting more granular temperature reports.

“[While] individual product temperatures are extremely important to the true impact on products, [so is] pinpointing temperature fluctuations and any unsafe drops in temperature while also providing defensible product temperatures,” says Sharpe. “Door openings during delivery can have a drastic impact on the temperature of food products. This means if the distributors are not monitoring at the pallet or product level, their reports are erratic data points that don’t show the true temperature of the product, placing unnecessary risk on your brand. These businesses can’t defend ambient/compartment temperatures and they don’t have to anymore.”

Furthermore, the ELD mandate created a scalable platform for the implementation of real-time location tracking solutions, allowing shippers and their 3PL partners to keep a close eye on highly perishable shipments like produce and frozen foods, says Corey Sergent, vice president of branch sales of GlobalTranz, Scottsdale, Ariz.

“Technology that prevents a break in the cold chain is also incredibly useful. For example, during deliveries, dock seals—large pads the trailer backs up to—form a seal between the building and truck, keeping pests and debris out while keeping the cold in," says Sergent.

Additional challenges include the inability for brands to properly track their products, product spoilage within the cold chain leading to shrink and waste and just a general lack of food safety standards awareness among some start-up brands, says Tom Woodward, chief commercial officer of Universal Pure, Villa Rica, Ga.

“All sectors of the food industry are impacted by improving food safety standards,” he adds. “Ensuring the safety of foods and beverages for consumers has to be a priority, no matter the cost. Since consumers are demanding fresh products with less additives, this sector will be greatly impacted. It is the industry’s job to make sure ready-to-eat products are available, but with the highest level of safety in mind.”

Why packaging matters

One of the most pertinent but often overlooked ways to keep the food supply chain safe is with the label, says Lee Patty, vice president and general manager of NiceLabel Americas, Wauwatosa, Wis.

“As consumers demand more transparency and FDA regulations continue to evolve, it’s critical that food and beverage manufacturers do more than simply comply with current legislation—they need a system that’s flexible and agile enough to adapt to future changes in the industry for tomorrow and beyond. Legacy processes and systems simply won’t suffice, and a mislabeled product can be devastating for a brand, and worse, potentially deadly for a consumer.”

According to a study from Digimarc Corp., the Beaverton, Ore.-based creator of the Digimarc Platform for digital identification and detection, for manufacturers that monitor label accuracy, 80% will report a problem from mislabeled products on their primary production line, and 67% still use manual inspection methods.

“Manufacturing quality requirements are becoming more challenging as speed of production and complexity of product lines increase,” says Bruce Davis, chief executive officer, Digimarc. “No reads and misreads of label matches on packaging can be very costly. The list of benefits of package enhancement for consumer brands continues to grow, providing further impetus for adoption.”

That’s why technologies such as label management systems allow manufacturers to implement a standardized method for producing labels and marking packaging across all processing locations. Food and beverage processors can also integrate labeling with other business solutions like manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. Meanwhile, cloud-based label management systems help companies store, change and approve all labels from a centralized location.

“Advancements like these can eliminate manual data entry errors and drastically reduce the potential of a recall due to a mislabeled product,” says Patty.

Improving food safety supply chain management

At the end of the day, when all is said and done, the last-mile carriers between the distribution center and store are the most impacted from a tampered food supply chain.

“These carriers are dealing with multiple stops, and when the doors are opened at each stop, the temperature in the back of the trailer can raise to unsafe temps, so product monitoring is key,” says Sharpe. “This is why pallet and product level monitoring are crucial in the transport of food. Gone are the days of looking at an ambient/compartment temperature reports with erratic data points tied to door opens and reefer shut offs. The new best practice is technology that gives real-time alerts, reporting on the pallet and reefer with a true read on the temperature of individual products. It’s really changed the game, allowing distributors and food operators to feel proud to share their temperature reports with their customers knowing they will solidify trust and safeguard them from FSMA fees and fines.”

To improve food safety in supply chain management is a combination of the people, processes and technologies involved, says Cahn, especially since specific sectors are more relevant than others when it comes to food fraud.

“Supplier relations programs and performance tracking is a key initiative for many organizations to begin with to help mitigate potential risk. Initiatives to track ingredients by a lot or supplier needs to be able to go beyond a single tier of visibility to a multi-tiered network for complete visibility. Today, resource and implementations of digital supply networks is only growing at this point to accommodate the food safety or quality risks beyond the first tiers in the supply chain,” he adds.

Additionally, there are several tools and technologies available to help food processors obtain—and sustain—a safe food supply chain. This includes everything from well-trained employees who strictly follow standard operating procedures to organizations who have adopted and implemented recognized quality processes and programs to highly sophisticated pasteurization equipment such as high-pressure processing (HPP), says Tom Woodward, chief commercial officer Universal Pure, Villa Rica, Ga.

"Robust inventory tracking and management systems also provide a vital step, allowing brands visibility throughout processing and distribution," adds Woodward. "Processors must be willing to constantly seek ways to improve safety, and they must be willing to commit the appropriate resources. All sectors of the food industry are impacted by improving food safety standards."

Likewise, a growing array of sensors that monitor temperature, as well as shipment location, transit time and other metrics during transportation, are available for food processors prioritizing a safe food supply chain, says Corey Sergent, vice president of branch sales for GlobalTranz, Scottsdale, Ariz.

"The ELD mandate has created a scalable platform for the implementation of real-time location tracking solutions, allowing shippers and their 3PL partners to keep a close eye on highly perishable shipments like pharmaceuticals, produce and frozen foods," Sergent adds. "Technology that prevents a break in the cold chain is also incredibly useful. For example, during deliveries, dock seals—large pads the trailer backs up to—form a seal between the building and truck, keeping pests and debris out while keeping the cold in."

Other challenges relate to changes in the environment leading to food contamination, changes in consumer preferences, ageing, demographics and habits, the limited ability to reduce foodborne illnesses by improving food safety-related behaviors and practices and overall price volatility, Cahn says.

“All processors can be strengthening the food safety culture in their operations,” adds Turney. “A strong food safety culture is a prerequisite to effective food safety management. We will not make dramatic improvements in reducing the burden of foodborne disease without doing more to influence how employees demonstrate a commitment to food safety in how they do their job.”

Plus, e-commerce giants and shifting consumer expectations are challenging the industry to be more agile and transparent than ever before, says Sergent.

“Doing so requires a very different approach to cold chain management and transportation. Rather than relying on full truckloads delivering into regional distribution centers, e-commerce cold chains rely on more frequent refrigerated less-than-truckload (LTL) shipments, originating from a larger number of conditioned warehouses (or even retail locations) located as close to the consumer as possible,” he says. “Experienced 3PLs can offer access to refrigerated truckload and LTL capacity in a tight market, and also provide entry to conditioned facilities for the storage of products throughout the distribution network. Some 3PLs offer real-time monitoring of temperature sensors to ensure the integrity of products in transit, while also mitigating claims and lost revenues resulting from rejected loads. Most importantly, a good 3PL can act as a strategic partner to develop a customized approach to a shipper’s transportation and logistics needs that are aligned with their goals and plans for the future.”