In today’s rapidly evolving food industry, ensuring the safety, quality, and transparency of products is more crucial than ever. As the food supply chain grows increasingly complex, grocers face mounting challenges in meeting strict regulatory standards while catering to consumer demands. To balance these complexities, grocers are turning to automation as a transformative force, redefining how food is handled, tracked, and delivered from farm to fork.

How automation improves traceability

Installed within warehouses and distribution centers (DCs), automation enhances traceability by enabling the precise tracking of products throughout the food supply chain. With automated storage and distribution systems in place, grocers can gather, store, and analyze data more efficiently, providing real-time insights into the movement of food from farm to fork. This level of traceability ensures that all stakeholders—whether farmers, processors, or retailers—can access accurate and up-to-date information.

Automation allows for seamless integration of data across various systems, such as warehouse management, inventory systems, and transportation logistics, ensuring that information is not only centralized but also accessible and actionable. This results in improved product visibility and accountability, enabling companies to quickly respond to safety concerns or potential issues.

Furthermore, automation plays a key role in supporting sustainability. By improving traceability, automation allows grocers to better understand the environmental footprint of their operations, from resource consumption to waste management. With more efficient systems in place, businesses can track and minimize waste, ensuring that resources are utilized more sustainably throughout the food supply chain.

Making compliance easier

With automation incorporated into their food safety strategies, grocers can significantly bolster their commitment to food safety compliance and reinforce their accountability to consumers. To meet strict food safety regulations, grocers must collect and maintain vast amounts of data on product statuses and movements. As regulations continue to evolve, managing this data becomes increasingly complex. Automation can streamline data collection, storage and reporting, making it easier for grocers to comply with these regulations.

From temperature monitoring during transport to batch-level tracking in warehouses, automation ensures that critical information is captured and stored securely. In the event of an audit or food safety inspection, this automated data can be quickly retrieved, reducing the risk of penalties and improving transparency. If a food safety incident or recall occurs, automated systems can quickly pinpoint affected products by tracking their location across the supply chain. By rapidly zeroing in on affected products with the help of automation, grocers can minimize disruptions, reduce the scope of the recall, and ensure consumer safety.

Proactive food safety

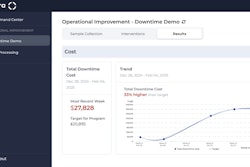

Automation doesn’t just help grocers react to food safety incidents—it helps prevent issues before they occur. By offering real-time monitoring and advanced data analytics, automated systems allow grocers to proactively identify potential risks in the supply chain. For example, temperature-sensitive products can be monitored continuously, ensuring that they are stored and transported under optimal conditions. This real-time oversight significantly reduces the risk of contamination and spoilage, keeping food safe from farm to fork.

Building consumer trust through transparency

In an age where transparency is a critical factor in building brand trust, grocers aim to offer consumers detailed insights into the origins of their food products. Through automation, grocers can turn transparency into a competitive advantage. The ability to trace food from farm to fork allows companies to provide proof of their commitment to safety, quality, and ethical practices, offering consumers a clear window into the entire lifecycle of their food.

With enhanced traceability, consumers can confidently understand where their food comes from, how it was processed, and whether it was sustainably sourced. Consumers can thereby make informed purchasing decisions, fostering trust between grocers and their customers. By clearly demonstrating the safety, quality, and ethical sourcing of their products, grocers can strengthen their brand reputation and differentiate themselves in a crowded market.

Investing in sustainability

From farm to fork, automation serves as the key to a smarter, more sustainable food industry. It enables grocers to closely monitor and control every step a product takes, resulting in minimized waste, reduced energy consumption, and better resource conservation.

Automation’s role in sustainability also extends to supporting sustainable business practices. With complete visibility into products and activities upstream, grocers can make sure they buy products from farms and processors that employ sustainable and ethical practices.

The future of grocery

The demand for transparency, accountability, and sustainability in the food industry will continue to grow. Grocers who embrace automation for food safety and traceability will be well-positioned to meet these rising expectations and maintain a competitive edge in a rapidly changing market.

Automation is not just a short-term solution; it is a long-term investment in the future of the food industry. As technology advances, automated systems will continue to integrate innovative tools like artificial intelligence (AI), machine learning, and the Internet of Things (IoT) to further improve efficiency, accuracy, and scalability. These cutting-edge technologies will enable grocers to stay ahead of emerging challenges and ensure the resilience of the food supply chain.

As grocers and suppliers continue to integrate automation into their operations, they contribute to a stronger, safer, and more sustainable food supply chain that can meet the demands of an ever-changing world.