**Content brought to you in partnership with Shipwell**

Supply chain managers worked from one location on hard-wired, antiquated systems. Then came the pandemic. It was the start of a series of major supply chain disruptions that continue today, according to Gartner Research. The disruptions are now the “biggest potential risk to economic growth overall and have huge impacts.” Disruptions today include tariff disputes, natural disasters, geopolitical unrest, and transportation capacity issues.

Experts agree: Solving these challenges that came up during the pandemic will create resilience in the supply chain and result in reliable shipping in the future, regardless of the disruption.

Challenge #1: A remote workforce can no longer share data in person, on a live board, single spreadsheet or (yikes) printed documents.

According to Gartner’s Carly West, Research Director for the Logistics and Customer Fulfillment Team, organizations continue to struggle with the large amounts of data they’re generating. Ignoring the available data just because your team is remote isn’t an option, she says: “Transportation leaders who don’t take advantage of the exponential growth in available internal and external data risk lagging in efficiency, agility and relationships with their stakeholders.”

Technology is the way companies can avoid falling behind, says West.

“Logistics leaders [need to] learn how to use different internal and data sources together and the different technology options available to best leverage advanced analytics.”

Gartner’s most recent research detailed the effects of technology – with the biggest being reduced costs and improved processes. Sixty-five percent of organizations surveyed were investing in emerging/new technology for advanced analytics and 33% are planning to invest.

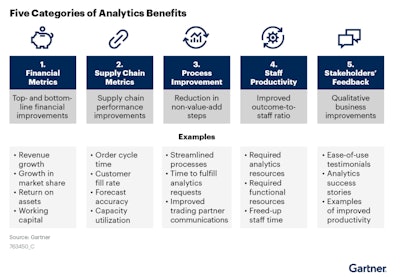

If your organization has struggled over the past two years under the crushing weight of Big Data rather than good data, West recommends creating a few top use cases for critical data based on the potential benefits in five key categories, then adding value to that raw data in the form of advanced analytics. Creating an ongoing value plan allows you to keep the momentum around strategic data integration going once you’ve achieved your initial goals.

Ultimately, good data will help you “sense the disruption, comprehend its magnitude and impact on the supply chain, and formulate a response.”

Challenge #2: Supply chain professionals need to be “always on” in multiple places at once, which is especially hard if they’re remote and if they’re implementing new technologies.

Even as employees are returning to their offices (and desks) they’re finding it hard to get their jobs done.

Shipwell supports the digital evolution of the supply chain industry, providing real-time data-based solutions around visibility, capacity and efficiency through their all-in-one TMS platform. The TMS platform is built to scale and saves time and reduces operating costs through shipment planning automation, replacing manual tasks to reduce operating expenses by 30%. Arrival time estimation and optimized routing guides built in helps expand capacity. These features help significantly when it comes to remote work and supply chain operation as a whole.

Shipwell was founded in 2016 by MIT graduates Greg Price and Jason Traff. Price brings a research background to the tech company, having started his career as a consultant with McKinsey & Co, while Traff, brings his background in business development, having previously founded a technology startup backed by Y-Combinator.

Recently the organization conducted a customer study to find out how often supply chain professionals who work in an office are away from their desk. The startling result? More than 75% of all supply chain managers spend at least some time during the week away from their desk. That’s not vacation time, either. It is time spent on the warehouse floor or overseeing teams.

“You should be able to work remotely and get your job done,” Shipwell’s Director of Product Marketing Aviad Benzikry says. “If you’re in a technology-enabled role especially, you need to be able to do that remotely. We’re not talking about driving a truck, which obviously you can’t do remotely. Being away from your desk realistically is going to be the norm going forward. Supply chain professionals need flexibility, and that will be a differentiator for all kinds of software as a service (SaaS) companies. Supply chain managers need to not be completely offline and unavailable as soon as they step away from their desk.”

The challenge for those organizations that view a distributed workforce as a “problem” is that implementation of new technologies like a transportation management system (TMS) can become siloed, says Oscar Sanchez Duran, Gartner’s Sr. Principal Research Analyst in Supply Chain Research.

“Supply chain leaders often consider TMS implementation more of an IT project rather than a collaborative effort, missing key opportunities to review and redesign their current processes to gain efficiencies with the support of TMS,” says Duran, who has authored a series of articles on how to successfully implement a TMS for Gartner.

If “out of sight” becomes “out of mind” in this phase, everyone loses. Benzikry suggests getting input from all stakeholders considering their unique needs.

“Integration and implementation are where the rubber meets the road. We think about the supply chain manager who is likely feeling the most pain. But what about everyone else? At Shipwell, we’re here to make you better at your job, to make you shine. We know the decision-maker is the director of transportation and/or logistics, and they want to see ROI. The CFO wants a supply chain that is a line item they don’t have to monitor day-to-day. The whole team needs to take part in the process.”

Challenge #3: Remote employees can’t access on-premises servers and the hard-wired technology they once relied on, leaving them disconnected from their most important tools.

This is where Shipwell has found a TMS solution that takes the old way of shipping and turns it on its head. Their recently launched Shipper Mobile app that allows teams to manage their supply chain from anywhere, resolving issues immediately and tracking shipments in real-time. Because it’s built for the remote organization, implementation can be done in half the time of an on-premises TMS.

“This is designed for the small screen in our hands. Most TMS’s have an app that is carrier facing. What’s different is to have an app that is shipper side. The Compass Dashboard has real-time visibility of where shipments are beyond just a map and corrective actions to proactively or reactively address issues. We also offer Responsive ETAs to understand traffic and weather impacts,” Benzikry says, likening it to consumer-facing technology. “Why not apply this to the most important thing, your business?”

Gartner named Shipwell “Niche Player of the Year” in both 2021 and again in 2022. Gartner’s Duran suggests that organizations approaching new TMS technology start first with change management.

“These operational changes driven by the TMS technology need to be backed up by senior executives and addressed as positive changes to the employees impacted by them,” Duran says, and the earlier the better.

Benzikry agrees. He says never lose sight of the goal of achieving an efficient supply chain.

“A supply chain manager is judged based on if things get to where they’re going on time and on budget,” Benzikry sums up. “It’s as simple as that.”

For more information, please visit shipwell.com.

**Content brought to you in partnership with Shipwell**