The balancing act between the expansion of the cold chain (with its inherent vulnerabilities) and the industry’s commitment to better safety (aided by an array of new tools) continues. One sign of progress in this shaky balancing act has been the finalization of the U.S. Food and Drug Administration’s (FDA’s) Food Safety Modernization Act (FSMA). Compliance dates for the rules vary, with enforcement for at least one of the rules starting as early as September.

FSMA provides all players in the cold chain–growers, processors, distributors, retailers and transporters–a more definitive roadmap to improve the safety of the food supply. While many players have already deployed safe practices that exceed FSMA standards, the law gives the FDA new enforcement powers that can encourage better practices to improve food safety.

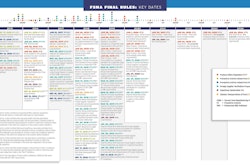

Earlier this year, the FDA finalized the last of the FSMA’s seven rules–the intentional adulteration rule. The intentional adulteration rule complements the preventive controls rules for human food and animal food, the produce safety rule, the foreign supplier verification program rule, the accreditation of third-party auditors rule and the sanitary transportation of human and animal food rule. These seven rules are designed to strengthen the food safety system.

The rules have varying compliance dates, depending in part upon the size of the covered business. The preventive controls rule for human food became final September 17, 2015, with a compliance date for certain provisions starting as early as September19, 2016, for large businesses. The sanitary transport rule was published in April and enforcement for large businesses begins in April 2017. The FDA has an educational outreach initiative, in addition to educational efforts from trade organizations and private efforts.

FMSA Borrows From HACCP

Some FSMA requirements are similar to longstanding practices such as the FDA’s Hazard Analysis Critical Control Point (HACCP) protocols. In formulating the final rules, the FDA incorporated certain HACCP-like elements–such as implementation of prerequisite programs, good manufacturing practices and analysis of potential problems and documentation–and shifted control measures to preventive measures.

The aspects of the law that are expected to have the most impact on supply chain service providers are the preventive controls and sanitary transportation rules. The preventive controls rule applies to companies involved in cold storage (in addition to manufacturing) while sanitary transport impacts companies involved in arranging shipping, loading, carrying and receiving food transported by truck and rail.

A survey of food industry companies on FSMA readiness indicated the preventive controls for human food requirements will have the most impact on their operations. Eighty-five percent of respondents, which included manufacturers, distributors, processors, retailers, transporters and brokers, report this rule will apply to them. (See sidebar on page XX.)

“You look at some of our refrigerated warehouse members, and at a very minimum, they’ll be a receiver under the [sanitary transportation] rule,” says Lowell Randel, vice president of government and legal affairs at the Global Cold Chain Alliance (GCCA). “Many of those warehouse members also will be loaders. And while not owning the product, warehouses often will be arranging for the transportation, and that’s an important distinction. The rule very clearly indicates that third-party entities, brokers and warehouses could very likely be shippers for the purposes of the rule, which means they will have this long list of responsibilities.”

“They may not see themselves as the shipper, but the rule will designate them as the shipper if they’re the ones who are arranging for a carrier to come in and pick up a load,” he says.

Most Extensive: Preventive Controls

The most extensive rule is the preventive controls for human food, Randel says. Companies registered as a food facility with the FDA must have a food safety plan unless they meet an exemption or a “modified requirement.”

The modified requirement applies when the facility is exclusively engaged in the storage of packaged product. In such cases, the law focuses on temperature control. The company needs a formal plan for maintaining the correct temperatures, corrective actions and verification procedures.

“Is it going to change a lot about the practices in a warehouse? Probably not,” Randel says of the temperature control requirement. “But it’s definitely going to be a lot of recordkeeping and documentation and to demonstrate to the agency, ‘here is how we are maintaining temperature.’”

Companies not subject to modified requirements face a more detailed process. “That’s going to be very much like a HACCP plan, although they don’t call it a HACCP plan,” Randel says. A company has to have control points for preventing possible hazards and how they will be addressed. The company has to keep extensive records and have qualified individuals on staff to oversee the plan.

“The biggest part companies will have to implement if they have not already is the preventive controls,” agrees Eric Wolf, food safety and quality assurance manager at Preferred Freezer Services, a cold storage operator. The biggest challenge for many companies under the preventive controls rule will be the need to conduct risk assessments and implement hazard controls, similar to HACCP, Wolf says.

Sanitary Transport: Changes Coming

For Preferred Freezer Services, the biggest change under FSMA has been to formalize its transportation procedures to comply with the sanitary transport (STH) rule. All 35 company warehouses are HACCP compliant and have robust compliance training programs, he says.

Preferred Freezer Services has built strong foundations for both preventive controls and transportation requirements through its BRC certification and compliance efforts, Wolf says. He is confident the company will be able to meet FSMA requirements.

Billy Adams, director of food safety at Americold, agrees that preventive controls are the most important aspect of the law for cold chain storage. But the STH is the rule that Americold is reviewing more carefully. “I do think that that one will be somewhat of a challenge for the industry just because it’s so new, so different. The FDA hasn’t been intricately involved in invoking regulations around transportation. Now they put some very specific expectations around responsibilities of the shippers, of the carriers and of the receivers. In a company such as ours, we actually play all three of those roles in some of our facilities.”

“We’re shipping product out on behalf of our customers, whether or not we’re the shipper of record,” he says.

A More Flexible Approach

Under the STH rule, the FDA removed prescriptive requirements for temperature monitoring devices and continuous monitoring during transport. The agency replaced these provisions with a more flexible approach that allows the shipper and carrier to agree to a temperature monitoring mechanism for shipping food.

The rule places the responsibility for determinations about transportation operations (e.g., whether food needs temperature control for safety and the relevant operating temperature and mode of temperature monitoring, whether particular clean out procedures are needed, and whether previous cargo must be identified) on the shipper.

The shipper can rely on contractual agreements to assign some responsibilities to other parties, such as a loader or carrier. “We believe the shipper is in the best position of the parties covered by this rule to know the appropriate specifications for transport of its food,” the rule states.

More Training Required

John Ryan, a food safety consultant who operates under the name Sanitary Cold Chain, says the STH rule requires training for all carrier personnel engaged in food transportation. Personnel must be trained in awareness of potential food safety problems that may occur during transportation and in basic sanitary practices to address potential problems.

The carrier is responsible for all functions assigned if they are performed by other persons, such as a driver that is employed or contracted by a trucking firm, Ryan says. A carrier also can be a receiver or a shipper if the person also performs the functions of those respective persons.

Americold monitors the temperature of product upon delivery to and before departure from its facilities or vehicles, but it can also monitor temperatures during transit if required by customers, Americold’s Adams notes. The method it uses depends on what the customer wants, which is what the STH rule requires. In some cases, the company monitors the temperature using electronic temperature loggers. In other cases, customers supply the loggers and Americold monitors them on their behalf. “That is something that could become more of a standard in the industry than it is today,” he says.

Adams doesn’t expect real-time temperature monitoring will become standard practice just yet due to the complexities of mobile communications for temperature logger devices.

He agrees with those who say companies correctly using HACCP will most likely be in compliance with FSMA. Under FSMA, companies may need to change some of the language in their safety plans.

“For example, in the past you might have had an allergen management program; now you may have to say, ‘I have a preventive measure to prevent allergen cross-contact. That is my allergen management program,’” Adams says. “You will have to make sure you’ve read through the entire preventive controls rule.”

The intentional adulteration rule may also impact storage companies, Adams says. The rule requires food facilities to conduct vulnerability assessments and establish mitigation strategies for those areas of the facility susceptible to “attack.”

J.Kings Food Service Professionals Inc., a full line foodservice distributor, has always maintained a food safety plan designed to exceed the existing regulations, says Kevin Peterson, executive vice president of operations. “While the additional FSMA regulations increase the need for staff training, recordkeeping and temperature monitoring, the majority of the requirements have already been in place at the company,” he says.

Greg Shields, transportation manager at Dietz & Watson, a manufacturer of delicatessen food, thinks the STH rule will require more extensive recordkeeping. He believes the real-time visibility of assets and the temperature control systems will enable his company to meet the requirements. One area that Dietz & Watson is trying to get a better handle on is how well the carriers it uses in outlying markets will meet the STH rule.

Drivers Must Be Ready

“Changes in driver training and the documentation of that training are the biggest changes for the industry,” says Todd Holt, president of transportation at NFI Industries, a global 3PL. “All drivers must be trained in the correct sanitation methods to ensure that every load moves safely and without the fear of cross contamination. That training must be documented and the records maintained. Non-driving associates also will be trained to ensure that proper documentation occurs.”

“We have also put in place the needed information technology infrastructure to ensure all records are maintained, stored and available as required,” he adds.

“There’s nothing in it that’s onerous; it should make the industry better,” says Ken Lund, vice president of operations at Allen Lund Company, a transportation broker. He notes that STH requires carriers to use clean equipment, but it does not specify what equipment and what sanitation processes. “The rules couldn’t anticipate all of the different scenarios,” he says. “What they said is you have to provide a clean trailer.” How recently a trailer has to be washed will depend on what product it was carrying and what product it will be carrying.

Better Communication Expected

Lund says this non-prescriptive approach will be good for the cold chain. “It does push communication,” he says. The law does not require temperature monitoring of produce, for example. Companies that have temperature monitoring have to keep records of it.

Lund thinks produce transporters who follow the best practices provided by the North American Produce Transportation Working Group, which the May issue of Food Logistics examined in detail, will most likely be in compliance with STH. “All the better companies already do a pretty good job of that,” he says.

Lund acknowledges the law requires more documentation, which is something he thinks will drive more companies to deploy transportation management system (TMS) software.

Extensive Recordkeeping

Records of what communication takes place between a shipper and a carrier concerning instructions on temperature and sanitation need to be available, says Ray Zujus, business development director for food and beverage at Telogis Inc., a mobile enterprise management software provider. Carriers need to keep records of vehicle performance, maintenance, location and how the vehicle is being driven. “This is a key part of an overall connected, vehicle-workforce-work strategy that ultimately drives safety, productivity and efficiency in food and beverage fleets,” he says.

The STH rule is the only FSMA rule that specifically targets transportation providers, but some of the other rules refer to the need to document transportation practices. Hence, shippers and receivers could be asking carriers to provide information to comply with FSMA rules beyond the sanitary transport rule.

Leonard (Bud) Rodowick, manager of strategic relations for food safety and OEMs at Thermo King Corp., believes carriers should have a thorough knowledge of the preventive controls and intentional adulteration rules.

The preventive controls rule requires a registered food facility to consider the effect of several elements on food safety, one being transportation practices and another being distribution, Rodowick notes. “It [the food safety plan] needs to address transportation and distribution operations,” he says. “It is due September 19.” The rule also requires such facilities to communicate the need for appropriate temperature control to the person transporting the food.

A shipper could expect a carrier to assume more of the responsibility for the condition of the product in transit, Rodowick says. “You as a carrier need to be having a conversation with your shipper,” he says.

Requirements are Specific

“The requirements of the various FSMA rules apply to specific entities,” says Smitha Stansbury, a partner in the FDA and life sciences practice at the King & Spalding law firm. “The rule on foreign supplier verification programs applies to ‘importers’ of human and animal food. The sanitary transportation rule applies to certain shippers, receivers, carriers and loaders. The preventive controls and hazard analysis requirements apply to registered food facilities.”

Some observers nevertheless have some concerns about the law’s effectiveness.

Rodowick is concerned about independent truckers that are not required to follow FSMA. Companies with less than $500,000 in annual sales are exempt. According to trucking industry statistics, that’s the majority of the trucking industry.

“If the industry generally outsources some portion of their business as a normal business practice, how does the industry deal with the shippers’ written procedures on equipment, appropriate sanitation and all of the written transportation operations requirements to these outsourced partners?” asks Don Durm, vice president of customer solutions at PLM Trailer Leasing. “I am sure that not all of these partners are large trucking companies, and this may be difficult for companies that outsource a high percentage of their loads to deal with this.”

Durm asks how a shipper who creates the operational requirements for a carrier will be able to transfer those requirements to a third party. “Will the carrier, once they arrange for a load with a third-party partner, now become the shipper? What are the transparency requirements to the original shipper as to knowledge of the third-party carrier used?”

The documentation will be a key focus for the FDA, Durm notes. “If the carrier now becomes the shipper, they will have to be aware that merely by transferring the previous shippers’ written requirements may not protect them from possible litigation/prosecution if the food should become unsafe during the new carrier transport,” he says.

The shipper will need to provide the carrier in writing all of the requirements to protect food from becoming unsafe. This will require a full understanding of the food product temperature tolerances and conditions that would render the food transported unsafe. “How will these carriers who source third parties who may now become the shipper insure that all of their documentation requirements are back up with the science?” he asks.

As the food industry works toward meeting the new regulatory requirements, efforts are underway by associations and other groups to develop resources to help companies with compliance. The International Refrigerated Transportation Association (IRTA), a core partner of GCCA, is scheduled to release a best practices guide to help industry comply with the Sanitary Transportation of Human and Animal Food rule in early August.

Most Companies Unsure of How to Meet FSMA Rules

Most food companies have or are considering systems to meet Food Safety Modernization Act (FSMA) regulations, but most do not have confidence that the systems will actually meet requirements, according to an FSMA readiness survey by The Acheson Group and Software Safety Chain. The survey queried manufacturers, distributors, processors, retailers, transporters and brokers on their FSMA readiness.

Three out of four respondents said their companies were not completely ready for FSMA compliance, even though large companies must comply with certain requirements by mid-September.

The survey indicated that: 1) more information is needed on meeting FSMA requirements, 2) companies need to understand how systems meet the requirements, 3) companies need to know what resources are available to meet FSMA, and 4) upper management needs to be more involved in the compliance process.

Among the FSMA’s seven rules, the preventive controls for human food rule was cited by the vast majority (85 percent) of companies as applying to their business.

All companies indicated there would be some difficulty in complying with FSMA. Only a minority of companies have plans in place for the following areas: document management (34 percent), audit management (30 percent), supplier compliance (27 percent), food safety program management (34 percent), laboratory information management (19 percent), and the Global Food Safety Initiative (GFSI) automation system (10 percent).

Most large companies indicated they are relying on hazard (GAP or GMP) analyses to prepare for the law. Most of these companies said they are not using outside sources to conduct their hazard analyses.

Only 10 percent of respondents indicated their food safety plans are fully updated.

The majority said they keep both paper and electronic records and have confidence in the accuracy, accessibility and functionality of those records. The majority also said they are confident they can produce the records within 24 hours for audits.

More than half of respondents were unsure if they will need more staffing or technology to comply with FSMA. However, three-quarters said they will not use outside resources to comply. These split statistics may indicate that companies need more guidance about the regulations, including information about available resources.