Every day brings more news about challenges for the food and beverage (f&b) supply chain: rising customer demands, government regulations, food safety concerns, etc. On the flip side of these sobering reports come a parade of technologies and innovations that promise ways to improve supply chain safety and efficiency: software, automation, cloud computing, etc.

In sifting through the pile of case studies, white papers and technology bulletins cluttering our screens, constructive messages can be heard above the chatter. Keeping lines of communication open with business partners (customers, suppliers, consultants and trade resources) will allow the supply chain decision makers to understand the changing technology landscape and develop an effective business plan.

The 2015 Material Handling Institute (MHI) Annual Industry Report, “Supply chain innovation – Making the impossible possible,” offers a blueprint for a business plan in today’s changing supply chain. The report was developed in collaboration with Deloitte Consulting LLP.

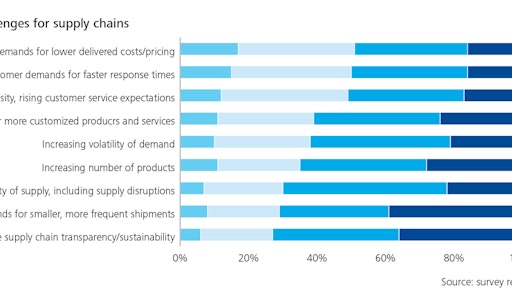

According to the survey, customer pricing pressure (51 percent), demands for faster response times (50 percent), and rising customer service expectations (49 percent) are the top three issues that supply chain professionals find very or extremely challenging. “Supply chains face conflicting demands to be better, faster and cheaper. Innovation is the key to achieving all three,” the report notes.

Dramatic change is coming

In 2014, MHI’s “U.S. Roadmap for Material Handling & Logistics” predicted that traditional supply chain models will undergo dramatic transformational change due to technological innovation and changes in customer demand through 2025. The survey identified eight technologies that are driving next generation supply chains:

- Inventory and network optimization tools

- Sensors and automatic identification

- Cloud computing and storage

- Robotics and automation

- Predictive analytics

- Wearable and mobile technology

- 3D printing

- Driverless vehicles and drones

Survey participants for this annual report included more than 400 supply chain professionals from a wide range of industries.

New fulfillment strategies

To address the challenges, many companies are changing their fulfilment strategies and holding inventory closer to key customers or markets and building specialized, high-velocity facilities. However, fulfillment strategies alone will not be sufficient to address the current and future challenges that supply chains face, the report notes.

For example, while holding inventory can buffer against uncertainty, it can also be expensive. Emerging technologies such as advanced inventory optimization tools can help supply chain companies make smarter decisions about where inventory buffers can be deployed most effectively.

Similarly, building distribution facilities for high-volume products can streamline shipments and reduce delivery costs. But for that fulfillment strategy to be cost efficient, companies need tightly-integrated planning and execution systems. Such systems often require some degree of automation.

Optimize Your Network

Network optimization tools help companies develop forward-looking scenarios that identify performance impact and associated risks, the report notes. These tools can be helpful in determining where to produce which products, where to hold inventory, which transportation modes to use, and how to differentiate service response times by product and customer.

“Material handling can no longer stand alone as an efficiency play inside the four walls of a warehouse,” says Mike Nayden, the leader of Deloitte Consulting LLP's logistics and distribution practice. Data proliferation and the emergence of data-driven technologies are creating opportunities for sharing information across the entire value chain.

Progressive companies are starting to leverage some of these new technologies and pursuing collaboration, the survey notes. Such initiatives include: using customer data (23 percent) or supplier data (16 percent) to drive predictive analytics; using cloud computing to collaborate with trading partners (20 percent); and using information from sensors and auto-identification to share and collaborate with customers and suppliers (22 percent).

The survey further found the leading barrier to investing in new technologies is the lack of a clear business case (36 percent). Lack of access to capital ranks as the lowest barrier to investment (25 percent), indicating that companies are able to invest, they just aren’t sure how to quantify the benefits in a way that justifies spending the money.

The leading game changers

The four technologies expected to have the greatest competitive or disruptive impact are: 1) optimization tools, 2) sensors and automatic identification, 3) robotics and automation, and 4) predictive analytics. The first three of these four technologies are already widely used in supply chains today.

Inventory and network optimization tools rank as the most widely used and most likely to deliver a competitive advantage. This is not surprising given their potential to significantly reduce costs without requiring a major capital investment.

The technology expected to have among the greatest competitive impact that has the least adoption among companies today is predictive analytics, which only 24 percent of surveyed companies use currently. However, as Figure 3 shows, adoption of predictive analytics is expected to climb to 70 percent over the next three to five years.

Predictive analytics is the application of advanced statistical analysis of structured and unstructured data sources to identify patterns and predict future events or outcomes. Predictive analytics can provide a look into the future and identify emerging patterns in the marketplace that can lead to effective and personalized customer engagement strategies.

This issue of Food Logistics explores how the f&b supply chain is embracing supply chain technology in the face of a changing market.